William Wipple Covell

- Born: 1844, Providence RI

- Died: 7 Jun 1915, Providence RI

General notes:

Jeweler

Events in his life were:

- He appeared on the census in 1870 in Auburn NY. Listed as a jeweler.

- He was issued patent number 191,665 on 5 Jun 1877

ANALDO M. ENGLISH AND WILLIAM W. COVELL, OF PROVIDENCE, R. I.

IMPROVEMENT IN THE MANUFACTURE OF PLATED JEWELRY.

Specification forming part of Letters Patent No. 191,665, dated June 5, 1877; application filed April 14, 1877.

To all whom it may concern:

Be it known that we, Analdo M. English and William W. Covell, of Providence, in the county of Providence and State of Ehode Island, have invented a new and valuable Improvement in Plated or Soft-Solder Jewelry; and we do hereby declare that the following is a full, clear, and exact description of the construction and operation of the same, reference being bad to the annexed drawings, making a part of this specification, and to the letters and figures of reference marked thereon.

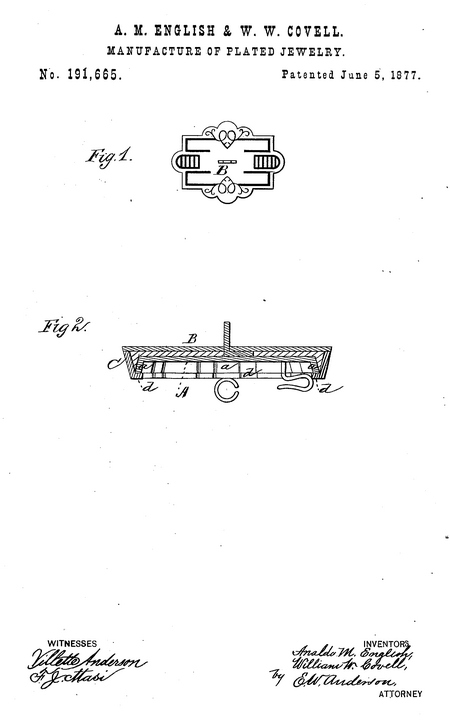

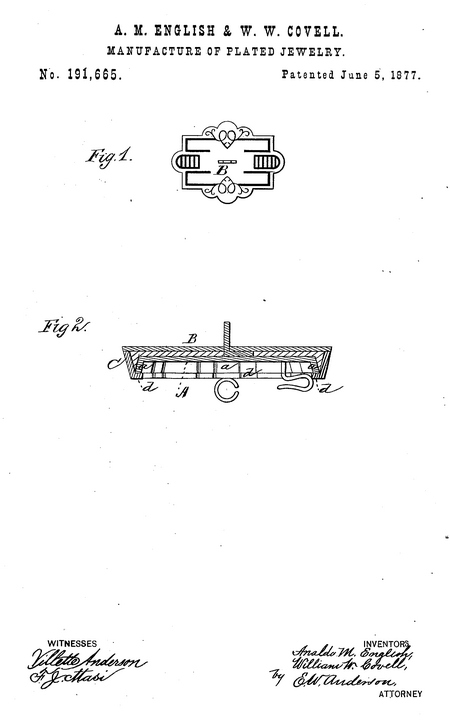

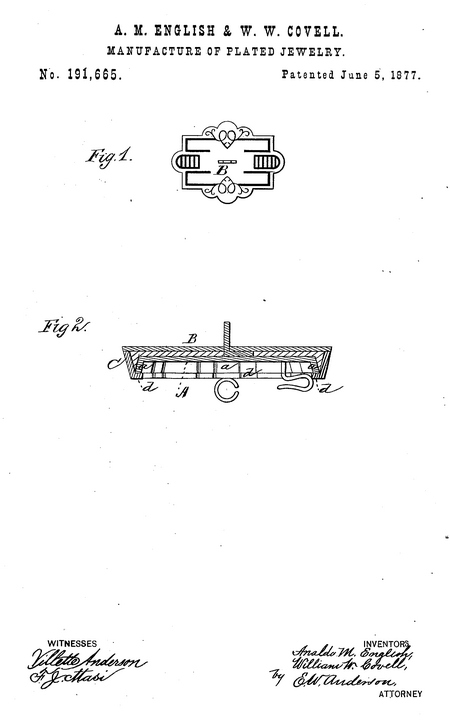

Figure 1 of the drawings is a representation of a top view of our invention, and Fig. 2 is a longitudinal sectional view thereof.

Our invention has relation to improvements in that class of jewelry known to the trade as "soft-solder goods."

It has long been an object in this class of jewelry to provide means whereby its outlines would be made to present that clearness and airiness of construction possessed in so marked a degree by the "shell-gold" class, in which the rim or bezel is usually soldered to a flat plate that forms the front or face of the work, and upon which the various processes of ornamentation and finishing are-carried out without forming indentations or other disfigurations upon the under side of said plate, thus leaving an even clean finish upon this side aforesaid.

In the manufacture of soft-solder goods, wherein "chasing" takes the place of engraving in ornamenting the front plate, it has heretofore been usual, in order to facilitate this operation, to fill the front or face with soft solder, to remove which is both difficult and, from the time required in so doing, inexpedient. Hence it becomes necessary to cover up the soldered surface, which is accomplished by making the work in two parts—the front and back plates—which are joined along their edges, thus completely covering up the baser metal, but at the same time causing the metal to prevent a certain clumsy, cumbrous appearance, which militates against its sale and general use, and which it is therefore very desirable to avoid.

To attain this very desirable result we have devised the following construction, a breastpin being used as an illustration of our invention:

The back plate A, which is usually and preferably of some base metal, is provided with a flange, a, at right angles to it, while the ornamented face-plate B may be of equal or greater dimensions than plate A, so that, when brought together the one upon the other, there may be a projecting edge, c, extending completely around it.

O represents a rim, or "bezel," as it is technically called in the trade, which is rigidly secured to face-plate A, and is provided with the flange d, projecting inward, as shown in Fig. 2, and overlying the flange a of the back-plate.

Usually the said rim will be inclined inward, and its outer surface will be at a bevel or acute angle with the face-plate. This latter being ornamented, by chasing or otherwise, previously to being attached to the back-plate, and being usually a plane surface, the solder may be readily and expeditiously removed, and it will lie snugly upon the back-plate, causing the whole pin to present an elegant light appearance.

In practice the rim or bezel is united to the back and face plates by soldering, the space between the flange a and the rim being completely filled up.

By this means the pin is made to present an appearance equal, in an artistic point of view, to the best shell-gold goods of the same description, and it is materially strengthened and rendered more durable.

What we claim as new, and desire to secure by Letters Patent, is—

In combination with the jewelry back-plate A, having a flange, a, the ornamental or face plate B, the rim or bezel 0, having an inwardly - projecting flange, d, overlying the flange a of the back-plate, substantially as specified.

In testimony that we claim the above we have hereunto subscribed our names in the presence of two witnesses.

Analdo M. English

William W. Covell

Witnesses:

Stephen Essex

D. W. Kimball

- He was issued patent number 217,801 on 29 Jul 1879

WILLIAM W. COVELL, OF PROVIDENCE, RHODE ISLAND, ASSIGNOR TO FREDERICK I. MARCY, OF SAME PLACE.

IMPROVEMENT IN THE MANUFACTURE OF WIRE FASTENINGS FOR JEWELRY.

Specification forming part of Letters Patent No. 217,801, dated July 29, 1879; application filed April 21, 1879.

To all whom it may concern:

Be it known that I, William W. Covell, of the city and county of Providence, and State of Rhode Island, have invented a new and useful Improvement in Wire Fasteners for Jewelry; and I hereby declare that the following is a full, clear, and exact description of the same, reference being had to the accompanying drawings, forming part of this specification.

This invention has reference to an improved method for securing wires to blanks used to be soldered to jewelry.

The object of this invention is to prepare these blanks and secure the wires without soldering any part thereof, so as to retain the hardness, springiness, polish, and color on the blank as well as the wire, and furnish the same to jewelers, ready to be secured, at the lowest possible price.

The invention consists,'first, in the method of manufacturing wire fastenings for jewelry which consists in stamping indentures and loops in the strip, inserting the wire through the loops, and securing it in place; and, second, in improved jewelers' stock, consisting of a strip of metal colored and polished on one side, tinned on the other side, and wired, as hereinafter described.

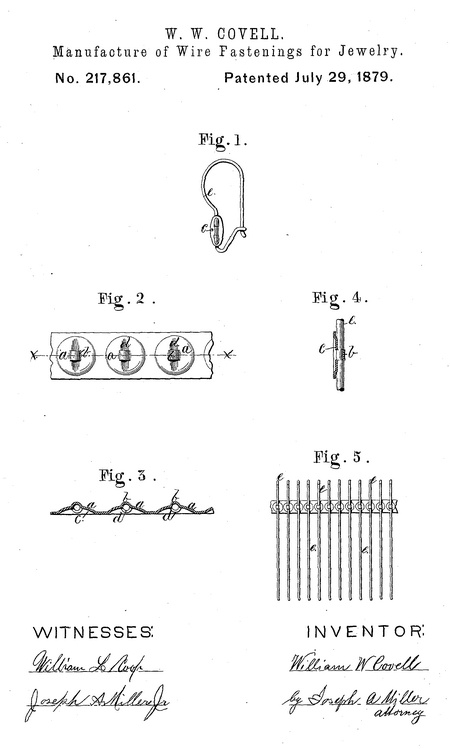

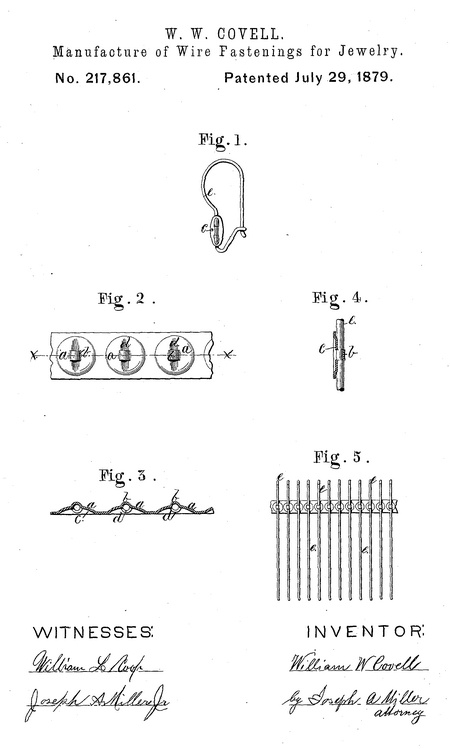

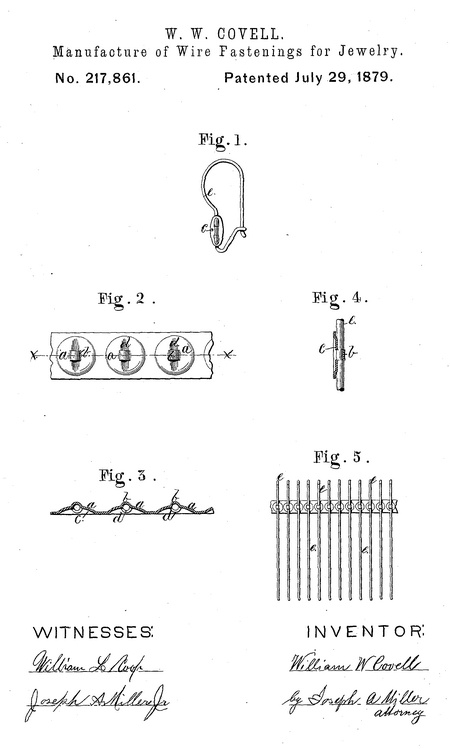

Figure 1 represents an ear-ring wire secured to a blank ready to be secured by ordinary soft solder to an ear-ring. Fig. 2 is a view of part of a strip of blanks stamped to receive the wire. These blanks may be used for earrings, shawl-pins, buttons, and various other pieces of jewelry to which wires are secured. Fig. 3 is a sectional view through the line x x, showing the configuration of the blank when stamped. Fig. 4 is a sectional view of the blank, showing the wire secured by pressure, whereby the loop on the blank and the edges of the blank are partially embedded in the wire. Fig. 5 represents a strip of blanks with the wires secured to the same.

Blanks to which wires are secured are manufactured and sold to jewelers and repairers of jewelry, to be secured to jewelry by solder. Such blanks were heretofore made of stock-plate or other metal, and when they were to be secured the surface to be so secured had to be covered with tin. This cannot be done, except with extra care, without exposing the surplus tin when the same is soldered to the article. This has to be removed and requires time, while the article itself is injured by the melted tin, which destroys the color and polish.

To avoid all these defects, I first tin one side of a strip or sheet of metal uniformly. I now stamp, in suitable dies, the concave indenture a, and at the same time form the loop b. The blank strip consists, therefore, of a number of concave circles or ovals on the tinned side e, and presents a number of convex circles or ovals, a, with the loop b and the indenture d, to receive the wire, on the polished side.

e represents the wire, which is passed under the loop b and lies in the indentures d d, each forming a semicircular channel, and the whole is compressed in a suitable-press, by which the loop is embedded in the wire, and the blank and wire are firmly secured together.

As nothing is soldered to the blank, and no heat is used in the construction, the sheets or strips can be colored and finished before stamping, and they will retain their color and polish ; and as the blanks are coated on one side with tin, they can be readily secured to jewelry without the labor, waste, and injury caused by securing the blanks as heretofore constructed.

As only plain sheets of metal and plain wire are used, they can be constructed at a lower cost than those heretofore made; and as no soldering is required, all skilled labor is dispensed with, and with proper tools they can be made by cheap and unskilled labour.

Having thus described my invention, I claim as new and desire to secure by Letters Patent—

1. The improvement in the art of manufacturing wire fastenings for jewelry shown and described, which consists in stamping the indentures d d and loop b, inserting the wire, and securing the same, as described.

2. Improved jewelers' stock, consisting of a strip of metal colored and polished on one side, tinned on the other side, and wired, as described.

William W. Covell

Witnesses:

Joseph A. Miller

J. A. Miller, Jr.

- He appeared on the census in 1880 in Providence RI. Listed as a jewelry manufacturer.

|