Julius Wilbur Rogers

- Born: 28 Aug 1853

- Died: 12 Feb 1879

General notes:

Silverplater

Events in his life were:

- He was issued patent number 197,408 on 20 Nov 1877

JULIUS W. ROGERS, OF WEST MERIDEN, CONNECTICUT.

IMPROVEMENT IN ELECTROPLATING-FRAMES,

Specification forming part of Letters Patent No. 197,408, dated November 20, 1877; application filed August 30, 1877.

To all whom it may concern:

Be it known that I, Julius W. Rogers, of West Meriden, in the county of New Haven and State of Connecticut, have invented a new Improvement in Electroplating-Frames; and I do hereby declare the following, when taken in connection with the accompanying drawings and the letters of reference marked thereon, to be a full, clear, and exact description of the same, and which said drawings constitute part of this specification, and represent, inó

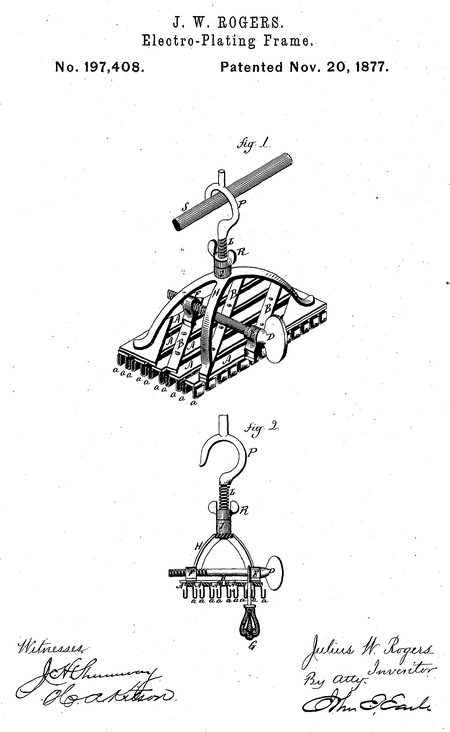

Figure 1, perspective view; Fig. 2, end view, sectional.

This invention relates to a device for holding articles to be electroplated, commonly called "plating-frame," and with special reference to plating articles in which only part of the article is to be coated, such as screw-heads, knobs, and the like; the object being to make the frame adjustable relative to the surface of the bath, so that only the article, or that portion of it to be plated, will be immersed; and it consists, substantially, in a frame attached to the pole by a screw-hook, the said hook adjustable in the frame, and combined with a set-nut to hold the frame when properly adjusted, and in details of construction, as hereinafter described, and more particularly recited in the claims.

In illustrating the invention, a frame for plating ornamental heads is shown. This is composed of several parallel bars, A, connected together by diagonal bars B, pivoted to each of the bars A, so that the bars A may be moved toward or from each other, and to thus adjust the bars relatively to each other a transverse screw, D, is held in a swivel, E, on one of the outer bars, and works through a swivel-nut on the bar at the opposite side, so that accordingly as the screw is turned the bars will be opened or closed. On the under side these bars are provided with springs a, at each edge of the said bars A, and more or less in number, the springs on the edge of one-bar having corresponding springs on the adjacent edge of the next bar, forming pairs of springs, which are adjustable relative to each other by the movement of the bars A, as above described, so that the shanks or part of the article not to be plated may be introduced between the. said springs, as indicated by the coffin-screw G, Fig. 2, each pair of springs holding its individual article as in a clamp.

To the bars A a yoke, H, is attached, at the center of which is a nut, I. Into this nut the screw L of the hook P is introduced, having first placed thereon a set-nut, R. This hook is for suspending the frame, and is hung upon the pole S, over the bath.

The screw on the hook P enables the adjustment of the frame to different elevations ; hence, to adjust the frame for plating, the hook is turned in the nut until that portion of the article to be plated will be entirely submerged in the bath, but the frame itself and the clamps will be above the surface of the bath; hence no deposit will be made on the part of the article which does not require to be plated, or on the frame itself, thereby effecting a great saving of the coating metal.

When the frame has been once adjusted the set-nut R is turned hard down upon the nut I, preventing any accidental disarrangement of the frame relative to the pole or surface of the bath.

Other holders may be substituted for the bars and clamps to adjust the frame to the particular article to be platedóthe yoke or support H, with its fixed nut I, and set-nut R, with a screw-hook whereby the adjustment is effected, being the essential feature of this invention.

I claimó

1. In a holder or frame for electroplating, the combination of the fixed nut I, set-nut R, and screw-hook, substantially as described.

2. The combination, in an electroplating-frame, of the adjustable parallel bars; and spring hooks or clamps on said bars, the hooks on one bar corresponding to the hooks on the next bar, substantially as described.

Julius W. Rogers

Witnesses:

Charles L. Wright

Henry L. Nichols

|