Robert Fitz Simmons

- Born: 25 Sep 1842, New York

- Marriage (1): Mary Stanley

- Died: 18 Sep 1894, Attleboro MA

General notes:

Jeweler and manufacturer

Events in his life were:

- He appeared on the census in 1870 in Attleboro MA. Listed as an ornamental engraver.

- General. R.F. Simmons Company of Attleboro was founded in 1873 by Robert Fitz Simmons, a chaser who conducted a small shop. Simmons struck up a friendship with Joseph Lyman Sweet who used to drive grain from the Sweet Farm in West Mansfield to Attleboro's town sales near Simmons' shop. In 1875 Sweet, Simmons, and Edgar L. Hixon formed a partnership, each investing $2,500 in the new business. In 1887 the organization had grown from 8-10 employees to more than 200, with offices in New York and agents in Rio de Janiero, Buenos Aires, Montevideo, Berlin, Barcelona and Sydney. Simmons' best known product was its watch chains, but other items were soon added to its line including chatelaine pins, eyeglass chains, fobs, bracelets and walking stick handles. It was around Simmons' 40th anniversary that it laid claim to numerous firsts in the industry, among them: First house to issue a chain catalogue 1881, first to stamp goods with the manufacturer's initials for identification, first to adopt the definite and responsible guarantee of satisfaction to the wearer--1880s, first to use a safety fastener in connection with chains and fobs--in the early 1890s, first to produce a practical lock bracelet -- the Marlow in 1899, etc. R.F. Simmons Company was active until 1952.

- He was issued patent number 225,879 on 23 Mar 1880

ROBERT F. SIMMONS, OF ATTLEBOROUGH FALLS, MASSACHUSETTS.

MANUFACTURE OF JEWELRY-CHAINS.

SPECIFICATION forming part of Letters Patent No. 225,879, dated March 23, 1880. Application filed July 19, 1879.

To all whom it may concern:

Be it known that I, Robert F. Simmons, of Attleborough Falls, in the county of Bristol and State of Massachusetts, have invented certain new and useful Improvements in the Manufacture of Jewelry-Chains, of which the following is a specification.

My invention particularly relates to chains of the kind known as "combination - link chains;" and its object is to produce a simple, strong, and durable chain of fine appearance.

My invention consists in a combination chain-link, comprising two opposite sides and ends, formed from a single blank or piece of metal, and separate pieces forming the intermediate sides, the said blank or piece having projections extending transversely from its opposite edges, made in the same piece with it and bent so as to form hollow cap-like ends, and the whole being organized and combined so that the intermediate sides are embraced and held in place by the hollow cap-like ends of the link.

It also consists in novel forms of blanks from which said chain-links are formed.

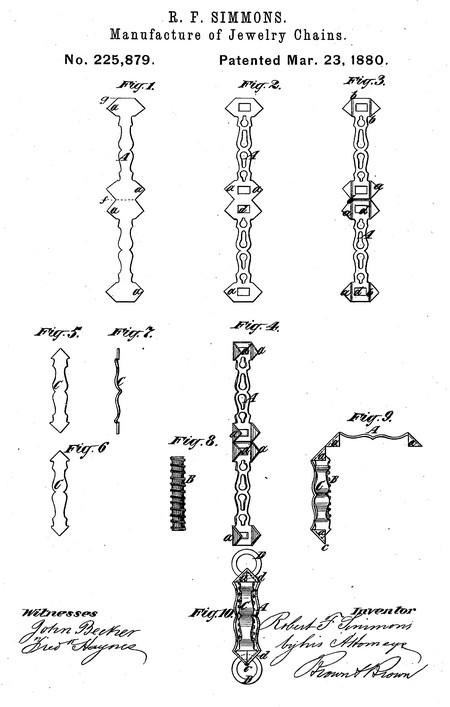

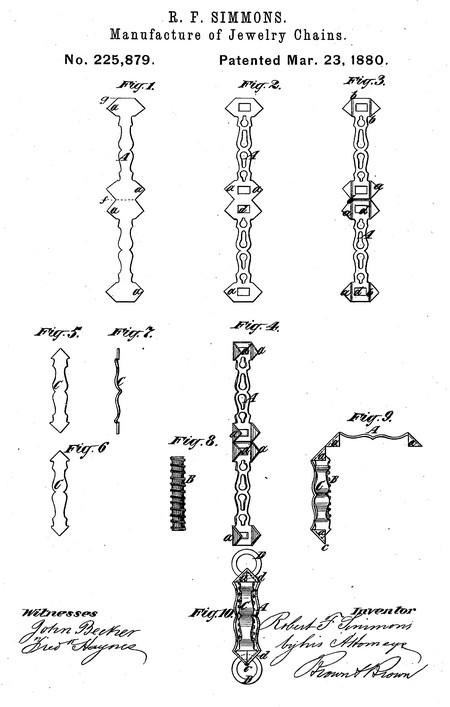

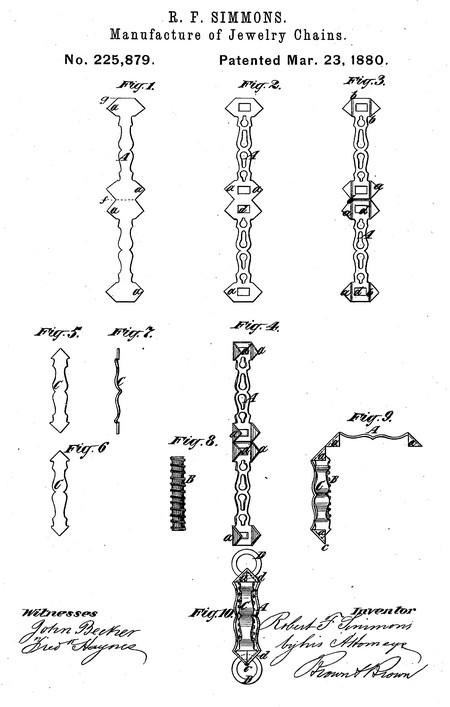

In the accompanying drawings, Figures 1,2, and 3 are face views of a plate-metal blank from which two opposite sides and cap-like ends of a link are to be formed, showing the same at different stages of its manufacture. Fig. 4 is a perspective view of the blank ready to be bent transversely to form the ends and sides. Figs. 5 and 6 are face views of the pieces intended to form two sides of the link. Fig. 7 is an edge view thereof. Fig. 8 is a side view of a spiral ornament intended to be secured in the center of the link. Fig. 9 is a side view of the blank, showing the same partially bent and the manner of securing the loose side pieces in position; and Fig. 10 is a side view of a finished link.

Similar letters of reference designate corresponding parts in all the figures.

Although the parts of which, my chain-link is composed may be otherwise formed, I prefer to cut the blanks from strips of metal already plated in any suitable manner, preferably by soldering thereto a thin sheet of precious metal. A, Fig. 1, designates one of the blanks thus formed, which may be of any suitable pattern. The blank is provided upon its edges with projections a, extending transversely from and made in the same piece with it, which are adapted to be turned up at right angles to the: body, forming cap-like ends, as shown in Fig. 10, and which may secure in place separate pieces or bars, forming two sides of the chain-link. The blank thus formed may be as represented in Fig. 1, or it may be perforated by means of suitable cutters, as illustrated in Fig. 2, and formed as shown in Fig. 9.

I preferably cut channels or grooves b in the blank, to facilitate the bending of the projections a, and these channels may have beveled sides, so that a miter-joint may be formed on turning the projections over, as represented in Fig. 4.

The blank A is preferably of sufficient length to form two opposite sides of a link, the blank being bent transversely at the dotted line /, Fig. 1, and the portion from f to g forming one side of the link.

B, Fig. 8, designates a spiral ornament, which may be placed in the center of the link, to add to its appearance and to stay or brace the same.

C (see Figs. 5, 6, and 7) designates side pieces, which may be cut from a strip of plated metal similar to the blanks A, and which may be formed as represented in Fig. 7, or left plain. The method of fastening these side pieces, C,in position is clearly illustrated in Figs. 9 and 10. The projections a, together with the body of the blank, form, when bent into the position shown in Fig. 10, hollow cap-like ends, and as the ends of the side pieces, C, extend into these ends, they are securely held in position. The several parts forming the link being placed in position, as shown in Fig. 9, the blank A is bent into the form represented in Fig. 10, and may, if desirable, be fastened by soldering at c.

D designates rings, of which any number may be employed, for connecting the links to form a chain, and which are represented as passing through perforations d in the links.

It will be seen that as two sides and the ends of the links may be formed from a single piece of metal, which serves to secure all the other parts of the link in position, and as only such parts of the link as are exposed need be plated, chains may be made in this manner very cheaply. The links, being only soldered at one place, if at all, are not liable to become broken by use, and do not, on account of discoloration through soldering, have to be refinished after soldering.

Although I prefer to make two sides and ends of the link out of a single piece of metal, I may employ two similar pieces, united at the ends of the link.

I am aware of Letters Patent No. 218,485, granted August 12, 1879, to J. P. Carpenter, and therefore I disclaim what is shown therein.

What I claim as my invention, and desire to secure by Letters Patent, isó

1. A combination chain-link, comprising two opposite sides and ends, formed from a single blank or piece of metal, and separate pieces forming the intermediate sides, the said blank or piece having projections extending trans-

versely from its opposite edges, made in the same piece with it and bent so as to form hollow cap-like ends, and the whole being organized and combined so that the intermediate sides are embraced and held in place by the hollow cap-like ends of the link, substantially as specified.

2. As an improvement; in blanks from which to manufacture ornamental chain-links, the form or shape of the double blank described, and represented in Fig. 1.

3. As an improvement in blanks from which to manufacture ornamental chain-links, the form or shape of the single blank described, and represented in Fig. 1 from letters f to g.

Robert P. Simmons

Witnesses:

O. B. Copeland

A. W. Blondin

- He appeared on the census in 1880 in Attleboro MA. Listed as a manufacturing jeweler.

Robert married Mary Stanley, daughter of David Thomas Stanley and Louisa Tyler. (Mary Stanley was born on 12 Dec 1845 in Attleboro MA and died on 10 May 1889 in Attleboro MA.)

|