Stephen Albert Briggs

- Born: 28 Mar 1849, Attleboro MA

General notes:

Jeweler

Events in his life were:

- He appeared on the census in 1880 in Attleboro MA. Listed as a manufacturing jeweler.

- He was issued patent number 367,087 on 26 Jul 1887

STEPHEN A. BRIGGS, OF ATTLEBOROUGH, MASSACHUSETTS.

LOCKET.

SPECIFICATION forming part of Letters Patent No. 367,087, dated July 26, 1887,

Application filed May 20, 1887. Serial No. 238,856.

To all whom it may concern:

Be it known that I, STEPHEN A. BRIGGS, a citizen of the United States, residing at Attleborough, Bristol county, State of Massachusetts, have in vented a new and useful Improvement in Lockets, &c.; and I do hereby declare the following specification, taken in Connection with the accompanying drawings forming a part of the same, to be a description thereof.

The invention relates to the halves or members of a locket to button-heads, breast pin fronts, &c.; and the improvement consists in such an article made of a single piece of stock struck up or formed into a cup, and swaged so as to produce an edge which overhangs or projects beyond the rim of the article, which edge is beaded or ornamented by pressure or shaping, whereby an article is furnished having an ornamental projecting edge in close imitation of the effect secured by soldering a beaded or ornamental wire around the rim of the article.

The object of the invention is to produce the article having an ornamental edge from one piece of metal, thereby avoiding the use of solder and securing greater, strength and durability.

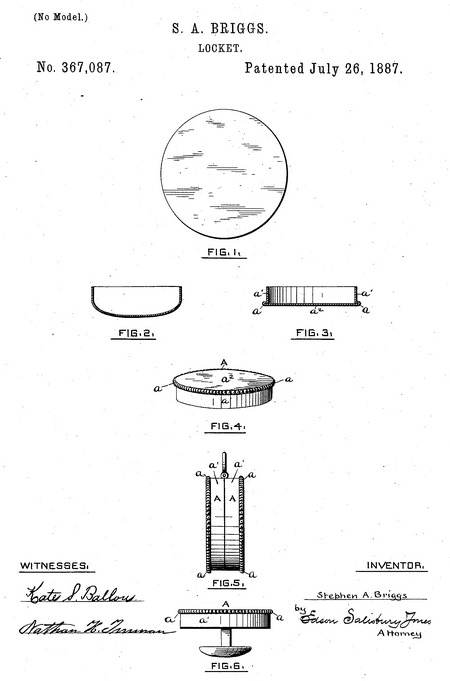

In the accompanying drawings, Figure 1 represents a blank in the form of a disk of metal from which the article of a circular form is made. Fig. 2 shows in section a cup struck up or formed from said disk. Fig. 3 represents in section the cup when it has been swaged to produce an overhanging edge projecting beyond the rim at its junction with the front. Fig. 4 shows in perspective the article with such edge beaded or ornamented. Fig. 5 represents a locket composed of two of the members. Fig. 6 represents the article used as a sleeve-button head.

The article maybe circular, oval, or polygonal, and in accordance with its form a blank is used to secure the best results. If the article is to be circular, a blank in the shape of a disk, Fig. 1, is preferably employed, and this blank, by means of proper tools and machinery, is struck up or formed into a cup, such as shown in Fig. 2. By means of other tools and machinery adapted for the purpose, this cup is then swaged into substantially the form shown in Fig. 3 to produce an edge, a, projecting beyond the rim portion a' and integral with said rim and the front a2 of the article, which front may be flat, as shown in the drawings, or of any plain or ornamental form or contour desired. The projecting edge a having been given to the cup, said edge is then operated upon by a beading or knurling tool or other pressure tool or tools, so as to produce a "bead," "rope," or ornamental molded edge around the rim, so that the article A when completed bears a close resemblance to one in which the ornamental molding is soldered to the rim, as in expensive jewelry. From the fact that in my improved article the ornamental edge is integral with the rim and front, all soldering is avoided, a re-enforcing effect is produced, which secures greater strength and durability, and the cost of manufacture is decreased.

The article thus made may be combined with a fellow to form a locket, as shown in Fig. 5, or may be used for the front or head of a sleeve-button, as shown in Fig. 6, or as a breastpin - front, as will be readily understood.

What I claim, and desire to secure by Letters Patent, isó

The article A, formed from a single piece of stock and having its front rim and an edge, a, projecting beyond the rim, all integral, the said edge being beaded or ornamented, substantially as set forth.

Stephen A. Briggs

Witnesses:

Edson Salisbury Jones

Kate S. Ballou

|