Arthur E. Codding

- Born: Dec 1842, Attleboro MA

- Marriage (1): Alice Amelia Chamberlain on 4 Jun 1868 in Attleboro MA

General notes:

Jeweler

Events in his life were:

- He appeared on the census in 1870 in Attleboro MA. Listed as a manufacturing jeweler.

- Patent: 10,848, on 1 Oct 1878. ARTHUR E. CODDING, OF ATTLEBOROUGH, MASSACHUSETTS

DESIGN FOR ORNAMENTAL TRIMMING FOR JEWELRY.

Specification forming part of Design No. 10,848, dated October 1, 1878; application filed August 19, 1878.

[Term of patent 7 years.]

To all whom it may concern:

Be it known that I, Arthur. E. Codding, of Attleborough, county of Bristol, in the State of Massachusetts, have originated and designed an Ornamental Trimming for Jewelry, of which the following is a full, clear, and exact description, reference being had to the accompanying drawings, forming part of this specification, and in which—

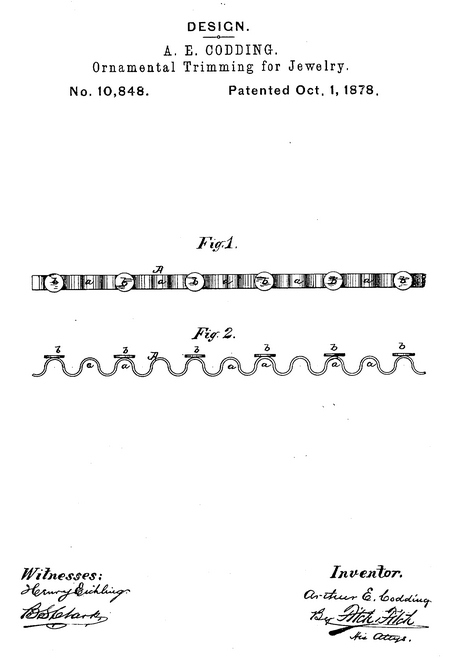

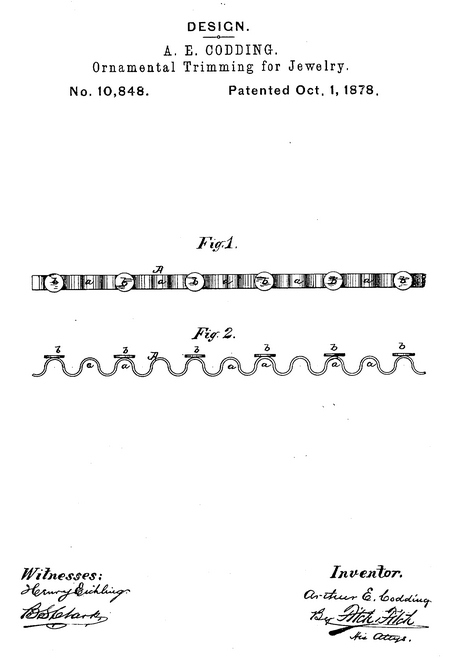

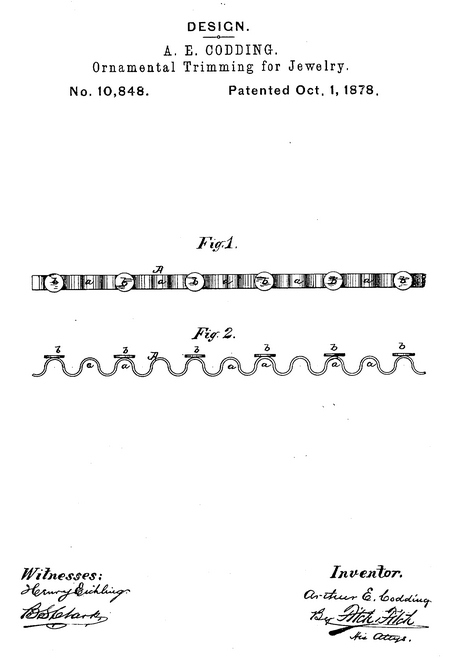

Figure 1 is a plan or face view of my ornamental trimming for jewelry, shown on a somewhat enlarged scale, and Fig. 2 is a side or edge view of the same.

A represents a strip or ribbon of metal, which may be gold or silver, or other metal, and may be colored to suit the taste. This strip is crimped, so that the curves a extend across it transversely, as shown. Upon the apex of the curves of these crimps, on one side or face of the strip, are placed the lustrous or polished disks b. These disks may be circular in outline, or may be polygonal, and may be placed upon the apex of each curve of the crimps, or upon alternate apices, as shown in the drawing.

The strip or ribbon thus crimped and ornamented with the lustrous disks, as described, may be employed upon all kinds of jewelry— such as pins, ear-rings, bracelets, buttons, and as a gem-setting—as an ornamental trimming to such jewelry.

I am aware that a design for jewelry has been heretofore made and used in which a ribbon of metal has been fluted or corrugated longitudinally and coiled into a spiral, with caps or disks fixed on the apices of the spiral curves. I do not, therefore, intend to claim, broadly, adesign for jewelry in which is a fluted ribbon wound or arranged in curves with caps or disks on the apices of the flutes or curves; but I desire to limit my claim hereunder to the specific design shown and described, which is a metal ribbon crimped transversely, and having the lustrous or polished metal disks in the apices of the curves or crimps, as set forth.

What I claim as my invention is— The design for an ornamental trimming for jewelry composed of the strip or ribbon A, crimped transversely, as at a, and lustrous polished disks b on the apices of the curve of the said crimps, substantially as described, and shown in the accompanying drawing.

Arthur E. Codding

Witnesses:

Jas. A. Codding

Edward R. Price

- Partnership: James & Edwin Codding and Leo Heilborn, in 1879-1918, in Attleboro MA. As CODDING BROTHERS & HEILBORN.

- He appeared on the census in 1880 in Attleboro MA. Listed as a manufacturing jeweler.

- He was issued patent number 236,552 on 11 Jan 1881

ARTHUR E. CODDING, OP ATTLEBOROUGH, MASSACHUSETTS.

BRACELET.

SPECIFICATION forming part of Letters Patent No. 236,552, dated January 11,

1881. Application filed August 31, 1880.

To all whom it may concern :

Be it known that I, Arthur E. Codding, of Attleborough, in the county of Bristol and State of Massachusetts, have invented a new and useful Improvement in Bracelets; and I do hereby declare that the following is a full, clear, and exact description of the same.

My invention relates to an improvement in the construction of bracelets; and its object is partly to simplify and cheapen the construction of such articles, and to further admit of the employment of a greater diversity of ornamental designs for the outside of the bracelet.

My invention consists in securing to a shell or back piece having holding-plates an outer removable face-plate of thin metal or any other suitable material, upon which the ornamental design is produced.

In the accompanying drawings, Figure 1 is a central vertical section through a finished bracelet. Fig. 2 illustrates the manner of attaching the removable face-plates. Fig. 3 represents a modification in the form of the back plates.

In these drawings, A A represent two curved back plates, constructed of gold or other suitable metal. The edges of these plates are turned over and rounded, as shown in Fig. 2 at 11. At each end of each of these plates, in the depression formed by the upturned edges 11, are securely soldered plates 2 3, each of which is raised a little above the surface of the strip, bringing its upper face about flush with that of the upturned edges 11. The plates 2 are provided with the usual eyes, through which is passed the pin for hinging the two sections together, and the plates 3 are furnished with the usual fastening-catch for clasping the bracelet upon the arm of the wearer. The main purpose of these plates 2 3, however, is to afford a ready and convenient means for attaching the spring face-plates 4 4. These plates are constructed of suitable metal or other suitable material of any desired kind and quality, and are ornamented upon one side, as taste and fancy may dictate. The ends of the plates 4 are slipped under the raised plates 2 3 and are

held there by the spring of the metal, owing to its curved shape, filling the space or depression in the back plate and forming a complete and ornamental bracelet.

It is evident that different designs may be placed upon the back and front of the bracelet.

Under some circumstances the spring of the metal will be sufficient to hold the spring faceplates in position; but for greater security the plates 2 3 and the ends of the plates 4 may be provided with some simple catch or fastening device easily operated—such, for instance, as illustrated in the detached view in Fig. 1— which will allow such face-plates to be removed without difficulty, and yet prevent the liability of accidental displacement.

In this device an unlimited number of faceplates in different designs might accompany each pair of back plates. Should, however, it be desired to render the designs once placed upon the bracelet unchangeable, the faceplates may be secured by solder in the center of the back plate, and as there is no strain upon such plate there would be no liability of displacement.

Fig. 3 shows another manner of constructing the back plate, consisting in simply turning up the edge of said plate into a straight flange, which alters the appearance of the article and produces a different effect. By this construction is produced, at very small expense, an exceedingly ornamental article.

The advantage of providing interchangeable designs for a single article of jewelry will be at once apparent to those skilled in the art.

Perhaps the principal advantage to be derived from this device lies in the extreme cheapness with which it can be manufactured, for it is evident that the back plates may be made in large quantities and of plain metal, and without any ornamentation, while the face-plates may be likewise made separately and in different styles, and may easily be applied to the back plates, as required, obviating the necessity of making an entire bracelet at once of some arbitrary design.

Having thus described my invention, what I claim is—

1. In combination with the back plates, A A, plates 2 3, secured thereto, and the removable face-plates 4.

2. The combination of the back plates, A, 5 with the holdiug-plates 2 3, the face-plates 4, and a device for removably securing the part 4 to the parts 2 or 3.

In testimony whereof I have signed my name to this specification in the presence of two subscribing witnesses.

Arthur E. Codding

Witnesses:

J. E. Pond, Jr.

B. E. Blackiston

- He appeared on the census in 1900 in Attleboro MA. Listed as a manufacturing jeweler.

Arthur married Alice Amelia Chamberlain, daughter of Unknown and Amelia J. Robinson, on 4 Jun 1868 in Attleboro MA. (Alice Amelia Chamberlain was born in Dec 1846 in Attleboro MA.)

|