George Horace Wilcox

- Born: 22 Aug 1856, Meriden CT

- Died: 26 Nov 1940, Meriden CT

General notes:

Silverplater

Events in his life were:

- He worked circa 1875-1895 as a silverplater in Meriden CT for the MERIDEN BRITANNIA COMPANY. At his father's death in 1890, he became president of the firm. After it absorbtion into International Silver, he became vice-president of the parent company.

- He was issued patent number 263,527 on 29 Aug 1883

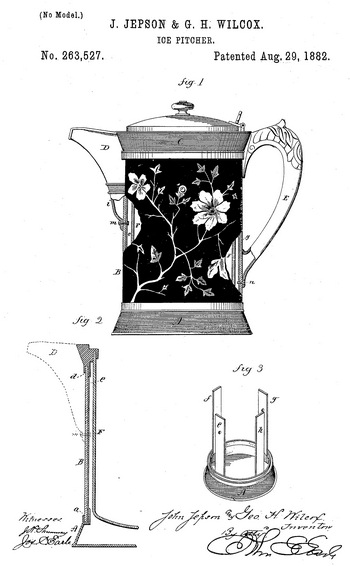

JOHN JEPSON AND GEORGE H. WILCOX, OF MERIDEN, CONNECTICUT, ASSIGNORS TO THE MERIDEN BRITANNIA COMPANY, OF SAME PLACE.

ICE-PITCHER.

SPECIFICATION forming part of Letters Patent No. 263,527, dated August 29, 1883.

Application filed July 31,1882.

To all whom it may concern:

Be it known that we, JOHN JEPSON and GEORGE H. WILCOX, of Meriden, in the county of New Haven aud State of Connecticut, have invented anew Improvement in Ice-Pitchers; and we do hereby declare the following, when taken in connection with accompanying drawings and the letters of reference marked thereon, to be a full, clear, and exact description of the same, and which said drawings constitute part of this specification, and represent, in—

Figure 1, a side view, portions broken away to show sections; Fig. 2, a vertical central section ; Fig. 3, the base detached.

This invention relates to an improvement in double-wall pitchers, the object being a construction which will enable the employment of papier-mache or similar material for the outer wall; and the invention consists in the construction, as more fully hereinafter described.

The general outline of the pitcher, as seen in Fig. 1, does not or need not differ materially from any of the shapes or styles in common use or well known, and in which A is the base; B, the outer wall; C the neck; D, the spout, and E the handle. The outer wall, B, is made from papier-mache or any suitable material, separate and independent from the other portions of the pitcher. The base A is constructed with a groove, a, at its upper edge, corresponding to and so as to receive the lower end of the outer wall, B. The neck C is made with a corresponding groove, d, to receive the upper end of the outer wall, B. To the neck the inner wall or vessel, F,is attached, so as to set within the outer wall and leave a space between the two, as seen in Fig. 2, and as usual in this class of pitchers.

To secure the parts together we employ several arms of metal, e f g h, the lower end made fast to the base by soldering or otherwise, as seen in Fig. 3, the length of the arms somewhat shorter than the height of the outer wall, and so as to stand vertically within the outer wall, and preferably so as to bear upon the inner surface of the wall, as seen in Fig. 2.

The spout D is formed on and as a part of the neck, its shell extending down onto the outer wall, as at i, and in a position in line with one of the arms—say e. Through the lower end of the spout-shell i a screw is introduced, passing through the outer wall and screwed into a hole made in the arm e, as seen at m, Fig. 1. On the opposite side the handle E is attached by its upper end to the neck 0, and at its lower end a screw, n, is passed through the handle, the outer wall, and into the metal arm g, as seen in Fig. 1. The parts set together as seen in Fig. 2, the screws inserted, the neck and base are bound together by means of screws through the handle and spout into the arms e g, iuside the outer wall, aud this securing being entirely independent of the outer wall—that is to say, the outer wall forms no part of the connection between the base and neck, but is itself held by means of the arms and the screws through the spout and handle. Thus no strain comes upon the outer wall, and it may therefore be made of many materials which could not be used were it necessary to secure the handle and spout to the outer wall. This construction therefore gives an opportunity to make the outer wall of a highly ornamental material and other than metal, whereby a most beautiful article may be produced.

In case the pitcher is designed to be supported iu a frame on trunnions r, these trunnions consist of a stud which is passed through the outer wall into the other arms, f h, inside of that wall. If such trunnions are not required, then the arms f h, may be omitted.

Instead of employing the spout and handle as the means for securing the parts together, other projections may be made on the neck, which will extend down onto the outer wall, and through which screws may be introduced the same as through the handle and spout. We therefore do not wish to limit our invention to making the connection through the spout and handle.

We are aware that pitchers have been constructed having an outer wall made of a material different from the neck and base, secured together; but we are not aware of such a construction of pitcher in which the neck portion is secured to the base by means of screws or other equivalents through the spout and handle, and through the outer wall into an arm, strip, or extension from the base.

What we claim, therefore, as our invention is—

1. In a double-wall pitcher, the base and neck, each independent of the other, the outer wall made independent of both neck and base, the neck and base constructed with arms extending up within tbe outer wall, with trunnions r, introduced through the outer wall and into the said arms, the said neck, base, and outer wall secured together, all substantially as described.

2. In a double-wall pitcher, the base and neck, each independent of the other, the outer wall made independent of both neck and base and constructed to rest at its ends, respectively, in the base and neck, the base constructed with anus extending up within the outer wall, the neck with projections extending down ward, and a connection made through said projections from the neck into the arms inside the outer wall, substantially as described.

3. In a double-wall pitcher, the base and neck, made each independent of the other, the outer wall made independent of both neck and base and constructed to rest at its ends, respectively, in the base and neck, the base constructed with arms extending up within the outer wall, the spout and handle attached to the neck and extending down onto the outer wall, with a connection made through, said spout and handle into the arms inside the outer wall, substantially as described.

John Jepson

Geo. H. Wilcox

Witnesses:

Richakd W. Miles

Geo. E. Savage

|