Matthias William Baldwin

- Born: 10 Nov 1795, Elizabethtown NJ

- Died: 7 Sep 1866, Philadelphia PA

General notes:

Jeweler

Events in his life were:

- Apprenticed: WOOLWORTH BROTHERS, about 1811, in Frankford PA.

- He worked in 1817-1825 as a jeweler in Philadelphia PA for the firm of FLETCHER & GARDNER. 34

- Partnership: Oren Colton, in 1819-1822, in Philadelphia PA. As COLTON & BALDWIN. 34

- General. In 1832, he built the first American locomotive and went on to found the Baldwin Locomotive Works in Philadelphia. He was a charter member and vice-president of the Franklin Institute 1855-1863 and was a member of the American Philosophical Society 1858-1863.

- He was issued patent number 5,789 on 19 Sep 1848

AZEL S. LYMAN AND MATTHIAS W. BALDWIN, OF PHILADELPHIA, PENNSYLVANIA.

IMPROVEMENT IN FOUNTAIN-PEN HOLDERS AND NIBS.

Specification forming part of Letters Patent No. 5,789, dated September 19, 1848.

To all whom it may concern;

Be it known that we, AZEL S. LYMAN and MATTHIAS W. BALDWIN, of Philadelphia, in the county of Philadelphia and State of Pennsylvania, have invented new and useful Improvements in Fountain - Pen Holders and Nibs; and we do hereby declare that the following is a full, clear, and exact description of the principle or character which distinguishes them from all other things before known and of the usual manner of making, modifying, and using the same, reference being had to the accompanying drawings, making part of this specification, in which—-

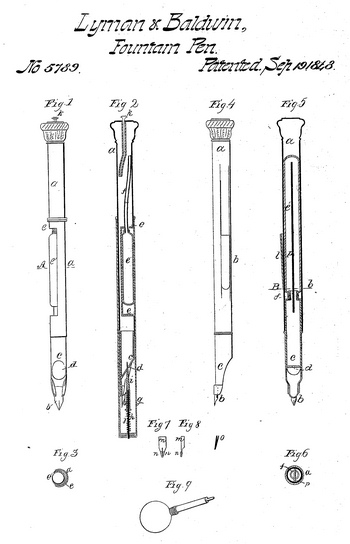

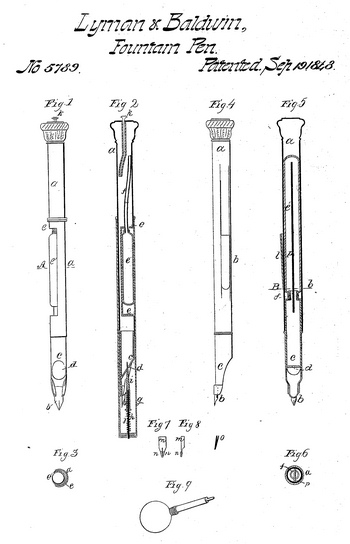

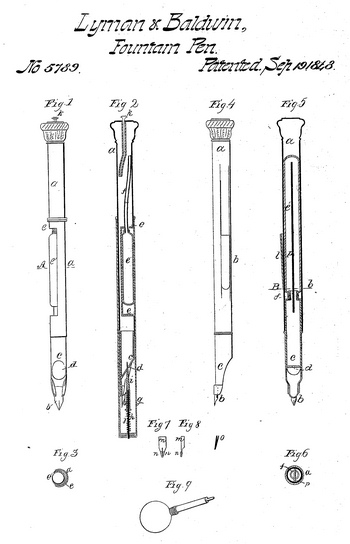

Figure 1 is a representation of our improved pen-nib and fountain-pen holder; Fig. 2, a longitudinal section thereof; and Fig. 3, a cross-section of the same, taken at the line A a of Fig. 1. Fig. 4 is a representation of a different mode of applying the principle of our improvements; Fig. 5, a longitudinal section, and Fig. 6 a cross-section, of the same, taken at the line B 5 of Fig. 5; and Fig. 7 is a front view of the pen-nib, and Fig. 8 an edge view of the same, and Fig. 9 a representation of an elastic pump for supplying the fountain with ink.

The same letters indicate like parts in all the figures.

The first part of our invention relates to the fountain-holder for supplying ink to the nib; and the nature of this part of our invention consists in supplying the ink to the pen from a bag or chamber, the whole or part of which is to be made of india-rubber or other elastic or yielding substance, air-tight except asmall hole for the supply of ink to the nib and placed within the handle or in a recess therein, so that the writer by making pressure with the finger or thumb will compress the bag or chamber and force out the required supply of ink.

The second part of our invention relates to the method of preventing the escape of ink when the pen is not in use, and consists in using a spring-plug attached to the inside of the cap or cover of the pen, so that when this is slipped on over the pen the said plug will enter the aperture through which the ink is supplied from the fountain to the nib, the tension of the spring retaining it there.

The third part of our invention relates to the method of preventing the elastic bag or ink-chamber from collapsing and adhering, which is effected by the use of a plate of metal or other substance placed within the bag, which prevents the inside surfaces of the india-rubber from being pressed together and adhering.

The fourth part of our invention relates to the method of making pen-nibs, and consists in making the point of the nib of metal put into nibs made of quill, whereby the durability of the metal for the point is combined with the elasticity of the quill-nib.

In the accompanying drawings, a represents the handle of the pen-holder, which is a hollow metal cylinder with the lower end provided with a nib b in any manner desired. The lower end c of the cylinder is closed, except a small aperture d, through which the ink flows from the fountain or reservoir in the handle to supply the nib. At e the metal of the cylinder is bent in to form a recess to receive a bag or chamber made of india-rubber or any of the compounds thereof or of other elastic substance which will retain ink, and the open end of this bag is properly secured to a neck or tube f, which communicates and extends up near to the top of the hollow handle. In this way when the hollow handle or fountain is filled with ink and the bag with air it will be perceived that when pressure is made either with the thumb or finger on the elastic bag the ink will be forced out by the elasticity of the air through hole d to supply the nib, thus enabling the writer, without the necessity of dipping, to keep his pen constantly supplied with ink; but the moment that the pressure is removed from the bag it expands by its elasticity and prevents the ink from flowing. When the pen is not in use, a cap-tube g, closed at one end, is slipped over the pen and the bag to prevent any accidental pressure from forcing out the ink. This cap-tube is represented by red lines in Fig. 2, and to the closed end of this cap-tube is attached a rod h, on which slides another rod i, a portion of which is hollow to slide on the rod h, and the point of the rod i is adapted to fit the hole d, through which the ink flows from the fountain to supply the nib, so that when the cap-tube is slipped over the pen the point of the rod i enters the hole d, and is there retained by the tension of a small helical spring j, and in this way the ink is effectually prevented from escaping, and hence the pen may be carried with safety in the pocket.

Instead of using the elastic bag as an air-chamber, it may be used as an ink-receiver, in which case the neck or tube f need not be extended up into the hollow handle, but simply communicate therewith, so that when ink is introduced into the hollow handle or fountain it also enters and fills the elastic bag. The ink is supplied to the fountain by an india-rubber pump. (Shown separately in Fig. 9.) It consists simply of an india-rubber bulb attached to one end of a tube, the other being adapted to fit a hole in the upper end of the handle or fountain. The bulb being supplied with ink, the tube is inserted in the fountain, and by making pressure on the bulb the ink is forced into the fountain and elastic bag, when desired. When the pump is removed, a ground-plug K is inserted in the hole to prevent the escape of ink. The fountain may, however, be supplied without a pump by compressing the elastic bag to force out the air and then permitting it to expand while the hole d is dipped in ink.

In Fig. o it will be seen that a strip of metal p is attached to the neck f and extends up into the bag. This prevents the india-rubber bag from being collapsed and the inside surfaces from adhering together.

Instead of placing the elastic bag in a recess made at the side of the handle, it may be let into the hollow cylindrical handle, as represented in Figs. 4, 5, and 6, the neck to which it is attached being reversed in this instance, and to make pressure on the bag when thus applied a portion of the tubular handle is slit longitudinally, as shown at v, to constitute a spring which rests against the elastic bag, before described, so that when this spring is pressed in by the finger or thumb it compresses the elastic bag and forces out the ink; or instead of this modification a piece of india-rubber or other elastic or yielding substance may be put over the recess in the side of the handle or over a hole in the handle. In short this may be variously modified so long as the whole or a portion of the reservoir or fountain is made of an elastic or pliant substance, which will readily yield to the pressure of the thumb or finger of the writer, so that the supply of ink to the nib maybe kept up while writing.

The nib m of the pen is composed of one piece of quill with a slit, or two pieces, properly secured in a holder in any desired manner, and the points of the two nibs are each plated with metal n n in the following manner: A thin piece of sheet metal (say gold or silver) is bent, as shown in the separate figure 0, slipped onto or over the nib and then pressed together and riveted thereto and properly pointed.- If desired to make the attachment more permanent, any suitable mastic or cement, such as shellac mastic, maybe used. In this way the durability of the metal point is combined with the elasticity of the quill. It will be obvious that instead of lining both surfaces of the quill, the under surface alone may be lined by using a strong mastic which will act on the metal and quill; but the mode described above will be found to be the best; and it will also be seen that the nibs thus formed may be used in connection with penholders of any suitable construction irrespective of the improvements in the fountain and holder described above.

What we claim as our invention, and desire to secure by Letters Patent, is—

1. The method of supplying ink to pens from a reservoir in the handle by means of a bag or chamber, the whole or part of which is made of gum elastic or other yielding substance, substantially as herein described, whereby the writer can by the pressure of the finger or thumb supply the nib with ink while writing, and thus avoid the necessity of dipping the pen.

2. The method, substantially as described, of preventing the escape of ink from the fountain by combining the spring-plug attached to the cap, as described.

3. Making pens by coating or plating quill-nibs with metal, substantially as described.

Azel S. Lyman

Matthias W. Baldwin.

Witnesses:

John W. White,

John Gamble.

- He was issued patent number 20,403 on 1 Jun 1858

M. W. BALDWIN, OF PHILADELPHIA, PENNSYLVANIA.

ATTACHMENT FOR WATCHES TO ASCERTAIN THE TIME WITHOUT LOOKING AT THE WATCH.

Specification of Letters Patent No. 20,403, dated June 1, 1858.

To all whom it may concern:

Be it known that I, MATTHIAS W. BALDWIN, of the city of Philadelphia and State of Pennsylvania, have invented a new and useful Improvement in the Construction of Watches; and I do hereby declare the following to be a full and exact description of the same, reference being had to the annexed drawing, making a part of this specification, in which—

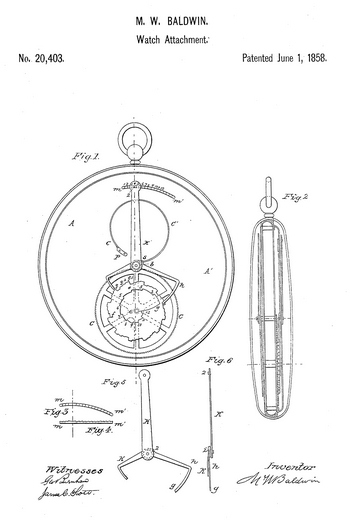

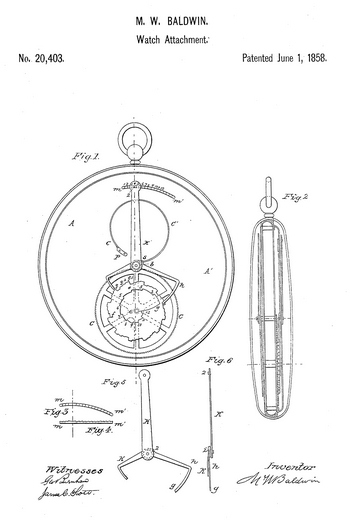

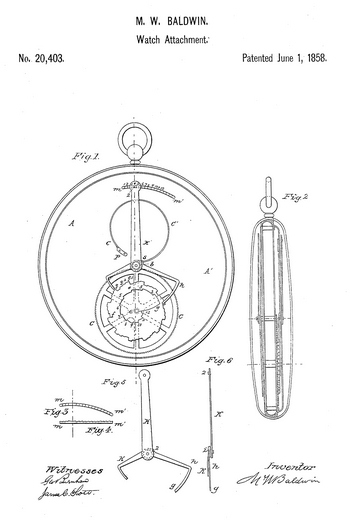

Figure 1, is a view of the back plate of the watch, showing my improvement attached. Fig. 2 is a transverse vertical section through the back plate and my improvement. Figs. 3, 4, 5, and 6 are detached views of parts of Fig. 2, shown in various positions.

My improvement consists in an attachment applicable directly to the ordinary watch, for the purpose of striking the hours and half hours and quarter hours whenever it is desired.

In the accompanying drawings, A, A', (Fig. 1,) represents the back plate of an ordinary watch; 5, represents a small pinion wheel attached to the journal of the center wheel, or minute-hand wheel, which journal is prolonged beyond its bearing inside, for the purpose of holding this pinionwheel 5. This wheel, 6, revolves with the minute hand. A larger spur-wheel, C, C, is centered and revolves on a stud, d, fastened to the back plate. This wheel, C, C, is geared into the wheel 5, and the cogs or spurs on & and c are so proportioned in number that the wheel C, C, will revolve one twelfth as fast as the wheel b. Securely attached to the outer surface of C, C, are two snails, e, and f. The snail f, being under the snail e. The circumference of the snail e, is composed of a series of projections, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, each at a gradually decreasing radial distance from the center of the snail e. These twelve projections are successively made to pass under the point g, of the bent lever h, as the hour hand makes twelve successive revolutions. Then, if the hour hand be so adjusted that the projection passes under the point g, at one o'clock, the projection 2 would pass under the part g at two o'clock, and so on, so that at twelve o'clock, the projection 12 would pass under the point g, and then at one o'clock, again, the projection 1 would pass again under the point g.

g, h, i, is a bent lever shown detached in Fig. 3, and in section at Fig. 4. It is shaped as shown in Fig. 3. and is attached to the case at the point h, so as to permit it to vibrate through a variable distance, as hereafter explained. An arm, K, is attached to the bent lever, g, h. i, so as to vibrate with the lever k. At the outer extremity of a small pin l, projects. Beneath the pin l, there is a small segment rack, m, m', which is subdivided from the point m toward m', into twelve ratchet teeth, as indicated by the numbers 1. 2, 3. 4, 5, 6, 7, 8. 9, 10, 11, 12. A spring, O, O', is permanently attached to the case plate at the point p. The other extremity of this spring S, rests against the bent lever, and tends to cause the bent lever always to occupy the position shown in the drawing. If the point l, on the arm h, be moved toward m', it will pass successively over the ratchets, 1, 2, 3, 4, 5, 6, &c., until the point g of the vibrating arm g. h, i. rests on one or the other of the projections, 1. 2, 3, 4, 5, 6, 7. &c., of the snail-wheel, e. If the hands on the face of the watch indicate one o'clock, then the projection 1. of the snailwheel e will be under the point g, and the point l of the arm m;, could only be moved over one ratchet on the segment m., m', when it would be arrested by the point g, of the lever g, h, i, striking the projection 1 on the snail-wheel e. If the hands indicated 2 o'clock, the point g would not be arrested until it touched the projection 2 on the snailwheel e. This would permit the point l to pass over two ratchets on the segment ratchet, m, m'. So, if the hands indicated three o'clock, the point l would be permitted to pass over three of the segment ratchets, m. m', before being arrested, and so on. successively for each hour up to twelve o'clock, after which the point l, would be arrested by the projection 1, on the snail-wheel e, as first above mentioned. As the point l, passes over each of the twelve ratchets of the ratchet segment, m, m', it makes a distinct clicking sound, so that the number of clicks heard indicate the hour which the hands would indicate on the face of the watch.

My improvement is of use in all cases when a person is unable, or unwilling to look at the face of his watch, and then he merely opens the back case, places his finger on the arm k, and moves it until he is unable to move it farther, and notices the number of clicks heard while moving it, and this gives him the exact number of the hour. The spring O always restores the lever g, h, i, and arm k, immediately back to its original position ready to be moved forward to determine the hour on a succeeding occasion.

The number of quarter hours after the hours clicked as above, which the hands would indicate as above, are shown by the similar arrangement of the snail-wheel f, and the part i, of the lever g, h, i, and the parts 0, q1, q2, qs, of the segment ratchet m, m'. The snail-wheel, f, is subdivided into 12 parts, and each of these twelfths is subdivided into four parts, o, q1, q2, qs. The part o, corresponds to the exact hour, as for example, 1 o'clock. The part q2 of the snail f, corresponding to the position of the hand indicating two quarters, (or half,) past. The part q3 of the snail f, indicating three quarters past. After the point l of the arm k has been moved toward m' until the number of the hour has been ascertained by the number of clicks emitted before the point g is arrested by one of the projections on the snail e, and after the spring O has returned the point l to the point n, or o, on the segment ratchet, the person should then move the arm k, and point l from n toward m, until its further motion is arrested by reason of the point i, striking against one of the projections q1, q2, or q3, and the person should note the number of clicks heard, and this will be the number of quarters of hours after the hour first struck. The point l does not rest on the ratchet segment, except when the weight or pressure of the finger is applied, hence in returning to its position at n, by the spring s, after having been moved from n toward m, or m', it passes clear of. the ratchets on the ratchet segment.

The advantage of this improvement is that it can be applied directly to any watch without deranging its existing machinery, and by means of it, any person can tell the hour and quarter-hour indicated on the face at night, in traveling, or under other circumstances, when desirable.

The pinion-wheel b, the spur-wheel, c, c', and the two snail-wheels, e, and f, may be attached to the back plate, A, A', and the spring 0, and lever g, h, i, may be attached to the inner side of the inner side of the inner casing, and the ratchet segment, m, m', and arm k, may be attached to the outer side of the same casing; or all these parts may be placed on the back plate.

Having thus described my improvement, what I claim as my invention, and desire to secure by Letters Patent, is,

The snail-wheels, e, and f; (or either of them;) the lever g, h, i, the arm k, and the segment ratchet, combined, and arranged as above described.

M. W. Baldwin

Witnesses:

Henby A. Marchand

Charles D. Freeman

|