Leroy S. White

- Born: 14 May 1828, Springfield MA

General notes:

Brassfounder

Events in his life were:

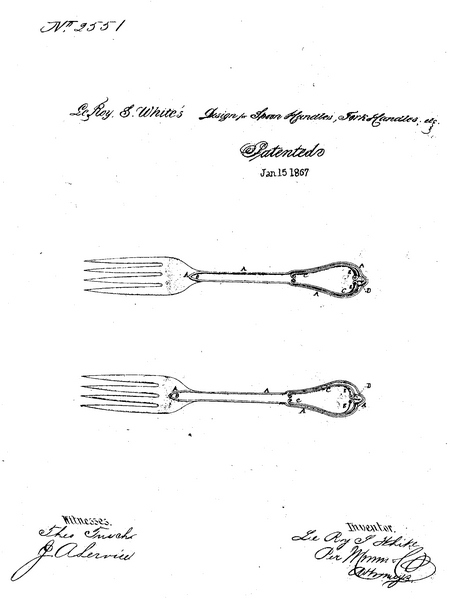

- Patent: 2551, on 15 Jan 1867. LE ROY S. WHITE, OF WATERBURY, CONNECTICUT.

DESIGN FOR THE HANDLE OF A FORK OR SPOON.

TO ALL WHOM IT MAY CONCERN:

Be it known that I, L. S. WHITE, of Waterbury, in the county of New Haren, and State of Connecticut, have invented a new and improved Design for Spoon Handles, Fork Handles, &c.; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawings, forming part of this specification, in which—

Figure 1 is a front view, and

Figure 2 is a rear view of the same.

Similar letters of reference indicate like parts.

The handle is made with a comparatively long and narrow stem or shank, and with low rounded shoulders upon its side edges, at the points where the said handle begins to expand or broaden, and terminates with a small rounded projection at the extreme end. Along the edges of the front and rear sides of the handle ia formed a single line, A, following the contour of the handle, and extending down upon the head of the fork or spoon in the form of a rounded angle, B; this angle extending further down upon the rear than upon the front side of said head. Along the sides of the broader part of the handle is formed a second line, C, terminating at each end with an inward curve and bead, as shown in figs. 1 and 2. ln the space between the end curves of the lines C and the line A, where it follows the outline of the rounded projection upon the end of the handle, is formed a shield, D, having a central longitudinal rib or raised line, as shown. E are short, curved lines, starting from the end curves of the lines C, and uniting with said lines at the broadest part of the handle, as shown in figs. 1 and 2.

I claim as new, and desire to secure by Letters Patent—

The design for fork handles, spoon handles, &c., herein shown and described.

LE ROY S. WHITE.

Witnesses:

David B. Hamilton, Charles A. Hamilton.

This patent led to the suit for design infringment, Gorham Co. v. White, 81 U.S. 511, 14 Wall. 511, 20 L. Ed. 731 (1872): . . . if in the eyes of an ordinary observer, giving such attention as a purchaser usually gives, two designs are substantially the same, the one first patented is infringed by the other. . .

The case was finally settled in Gorham's favour by the Supreme Court and is still considered the basic precedence in such actions.

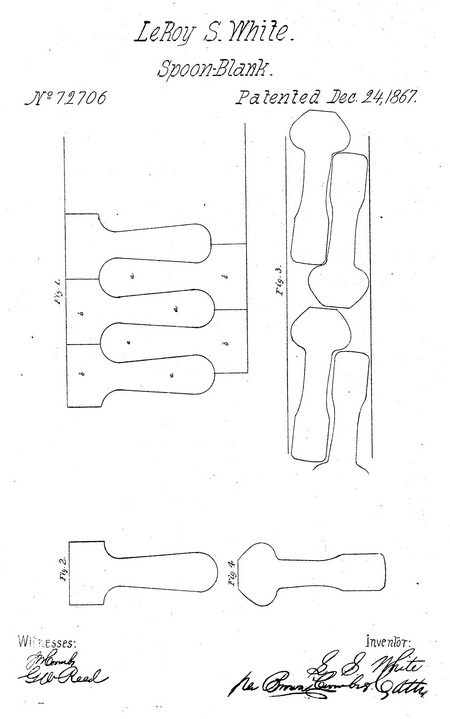

- He was issued patent number 72,706 on 24 Dec 1867

LE ROY S. WHITE, OF WATERBURY, CONNECTICUT,

IMPROVEMENT IN SPOON-BLANKS.

Specification forming part of Letters Patent No. 72,706, dated December 24, 1867.

To all whom it may concern:

Be it known that I, LE ROY S. WHITE, of Waterbury, in the county of New Haven and State of Connecticut, have invented a certain new and useful Improvement in the Manufacture of Spoons, of which the following is a full, clear, and exact description, reference being had to the accompanying drawing, forming part of this specification, and in which—

Figure 1 represents a diagram or face view of a bar or plate in part, illustrating the form and disposition of spoon-blanks cut according to my improvement; Fig. 2, a view of one of my improved blanks detached; and Figs. 3 and 4, similar views of the ordinary form and mode of manufacturing or cutting spoonblanks.

Like letters of reference indicate corresponding parts.

In the manufacture of spoons from German silver, or other like metal or alloy, it is quite an object, in cutting or stamping out the blanks from a bar or plate, to economize the scrap or waste by working the bar or plate into as many blanks as possible, heavy waste in the bar materially enhancing the cost of the blanks as they are furnished from the mill to the spoon-manufacturer. The after processes of rolling and stamping out the blank into a more finished shape, though usually entailing furtherwaste, the previous remarks, as regards the formation of scrap, are not designed to apply to.

The nature of my invention consists in so forming the blanks and arranging their cut out of the bar that, while giving the same a handle or shank and bowl character or shape, no waste or scrap occurs in cutting consecutively a series of such blanks.

Referring to the accompanying drawing, it will be obvious that, in shaping and arranging the blanks, as represented in Figs. 3 and 4, which is the ordinary mode of manufacture, a considerable waste takes place, or much scrap is formed, while by giving the spoon-blanks the form represented in Figs. 1 and 2, and stamping or cutting them reversely, each successive one, as regards the disposition of their shanks a and bowls &, and arranging them transversely of the bar A, the formation of all scrap or waste in producing a series of spoon-blanks is or may be avoided. The process of making the spoons from these blanks is substantially the same as that of making them from blanks of the form heretofore commonly employed.

What I here claim as new and useful, and desire to secure by Letters Patent, is—

The spoon-blanks of such form, and so cut or stamped out of the bar or plate without intervening scrap, substantially as specified.

Le Roy S. White

Witnesses:

Nelson J. Welton

Peter W. Powell

- He appeared on the census in 1880 in Waterbury CT. Listed as the superintendent of a brass mill.

|