Henry Bowers Winslow

- Born: 5 Jul 1824, Providence RI

- Marriage (1): Catherine Adelaide Knowlton on 19 Nov 1848 in Providence RI

General notes:

Jeweler

Events in his life were:

- He appeared on the census in 1860 in Providence RI. Listed as a jeweler.

- Patent: 130,015, on 30 Jul 1872. JOHN CALDWELL AND HENRY B. WINSLOW, OF PROVIDENCE, R. I.

IMPROVEMENT IN SLEEVE-BUTTONS.

Specification forming part of Letters Patent No. 130,015, dated July 30,1872.

To all whom it may concern:

Be it known that we, John Caldwell and Henry B. Winslow, both of the city and county of Providence, in the State of Rhode Island, have jointly invented a new and useful Sleeve-Button.

Our invention relates to that general class of buttons which are composed of a front plate and a separate combined shank and back plate, which are provided with ready means for connecting the two parts.

Our invention consists, first, in a novel combination of spring-yokes with the body and removable shank, by means of which the button may be used in garments which are provided either with the elongated or the circular button-hole, be very securely held in position, and be readily detached or inserted; and, secondly, in a novel method of securing the ornamental face-plate to the body of the button, and thereby give to it the general character of a locket; and we do hereby declare that the following specification, taken in connection with the drawing furnished and forming part of the same, is a true and accurate description of a button embodying the several and combined features of our invention.

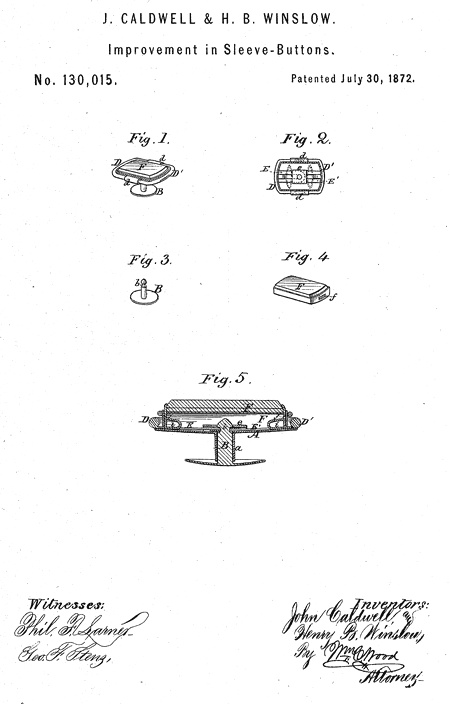

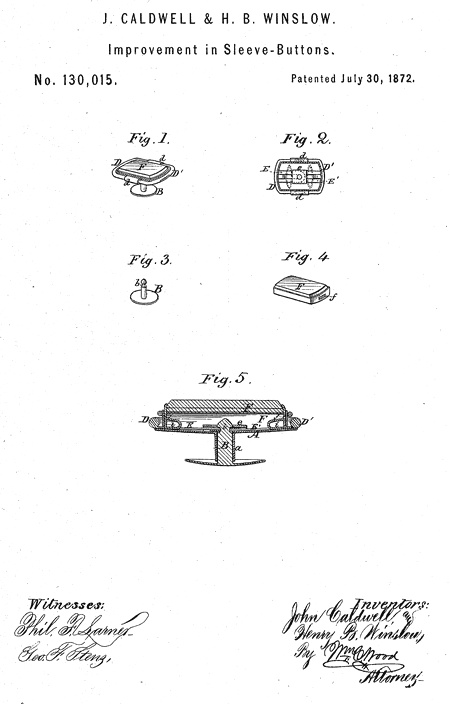

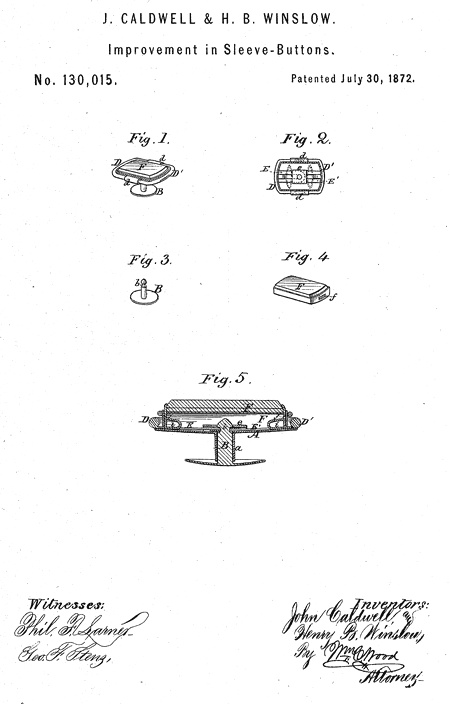

Referring to the drawing, Figure 1 represents one of our buttons in perspective. Fig. 2 represents the same in top view, with the face-plate removed. Fig. 3 represents the combined shank and back-plate detached. Fig. 4 represents in perspective the face-plate detached. Fig. 5 represents the button on an enlarged scale in longitudinal section.

A denotes the shell or body of the button. In this instance it is represented as rectangular and rounded at the ends. It is a hollow structure and slightly ornamented. B denotes the combined back-plate and shank. It is slightly conical at its end, and is fitted to freely enter a tubular socket, a, which projects at right angles from the rear side of the body A of the button. Adjacent to the end of the shank it is encircled by an annular recess, h, similar to many button-shanks of its class. D and D' denote two curved finger-pieces adapted to the configuration of the outer ends and sides of the body of the button, and are embraced on each side thereof by a tubular spring-chamber, d. Between the ends of the finger-pieces in each chamber d is an expansive spiral spring, which forces the finger-pieces apart, so that at each end of the button they will, on being, simultaneously pressed between the thumb and finger and released from pressure, be made to move longitudinally to and fro. E and E' are two slotted spring-yokes with closed ends. They are located within the body of the button, passing through slots in the ends thereof, and are attached to the spring-fingers at a transverse central point. As shown in Fig. 5, these spring-yokes are placed one above the other at their adjacent ends, their slots being coincident, and at their closed or inner ends they form a circular aperture coincident with the interior of the tubular socket a, and also with a circular aperture of corresponding size in a fixed guide-plate, e, beneath which the yokes slide. Assuming the shank and body of the button to have been separated, they would be practically applied for use as follows: The shank would be inserted through the button-hole, point outward, and the body of the button united by pressing the shank into the tubular socket a; by this action the conical point of the shank would force the spring-yokes to the right and left, advance through the opening, and by the force of their springs be suddenly and securely embraced by them. To detach the button slight pressure-at each end toward the center will compress the spring, advance the yokes toward each other, and release the shank. To detach the face-plate from the body of the button the same pressure on the finger-pieces is requisite, for thereby the bolts i will be withdrawn from the slots/in the ends of the face-plate and admit of its ready removal. To replace it the same pressure is requisite to admit the edge of the face-plate to pass down between the ends of the bolts i and the adjacent surfaces of the interior of the button.

Instead of using the external spring-chambers and the finger-pieces, the springs may as well be placed inside the button, and arranged to press the yokes D outward, by, for instance, having the springs abut against the rear ends of the bolts i and the adjacent edges of the guide-plate e. With such a construction the exterior ends of the spring-yokes might be ornamented and arranged for receiving pressure direct. The general form of the button can be readily varied to any desired extent, to meet the usual requirements of the trade.

We are aware that it is not new to combine spring-catches with the body and the removable shank of a button: but we are not aware of the existence of any combination and arrangement of these devices prior to oar invention by means of which the stud or shank at the annular recess has been embraced at opposite points by separate devices for that purpose. When embraced on one side only, and released by pressure applied at a single point, they are much more liable to loss by inadvertent detachment than when they require for displacement the moving of two releasing devices actuated by pressure in opposite directions. By having the embracing-yokes operated in different directions the extent of movement on each is about half that which would be required with a single catch, and therefore the necessary pressure-points for operating them are much less prominent, and hence less liable to be inadvertently operated than if the single yoke be employed.

We claim as new, and of our own invention, to be secured by Letters Patent—

1. In combination with the body and detachable shank of a button, the spring-yokes D and d1, arranged to embrace the shank at the annular recess on two sides, substantially as and for the purposes specified.

2. In combination with the shell of a button, the removable face-plate and the sliding bolts i, for detachably uniting the face-plate and the shell, substantially as described.

John Caldwell

Henry E. Winslow

Witnesses:

D. B. Potter

William B. W. Hallett

- He appeared on the census in 1880 in Providence RI. Listed as a jeweler.

Henry married Catherine Adelaide Knowlton on 19 Nov 1848 in Providence RI. (Catherine Adelaide Knowlton was born on 13 Aug 1826 in Providence RI.)

|