Edward B. Manning

- Born: Abt 1834, Middletown CT

General notes:

Pewtersmith

Events in his life were:

- He appeared on the census in 1850 in Middletown CT. Listed as a britannia worker.

- He appeared on the census in 1860 in Cromwell CT. Listed as a britannia worker.

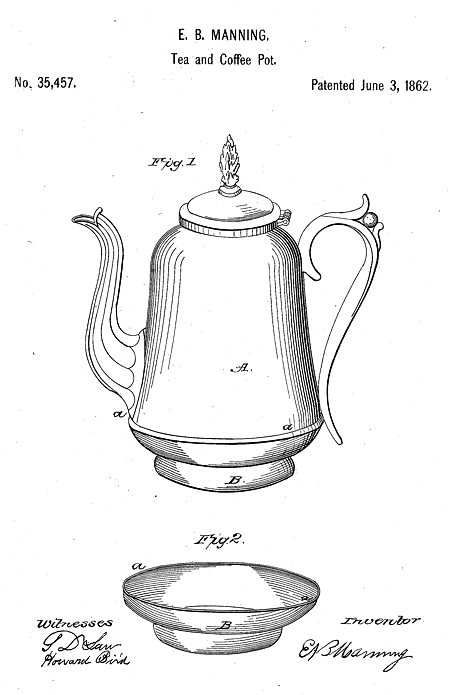

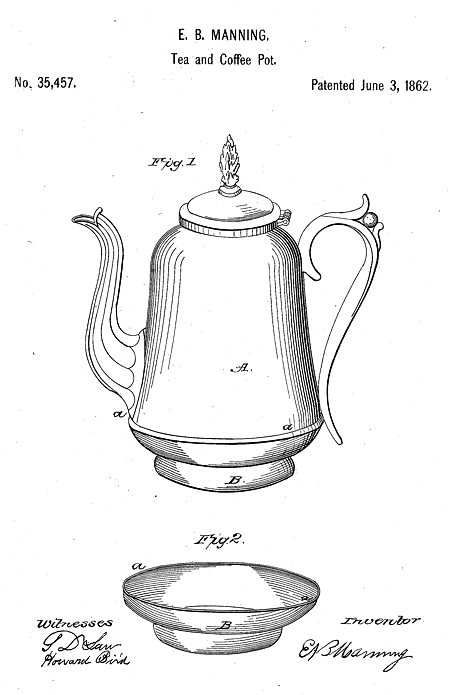

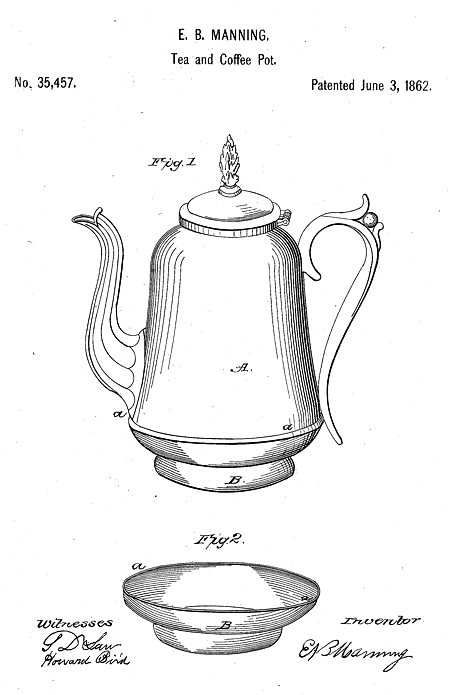

- He was issued patent number 35,457 on 3 Jun 1862

EDWARD B. MANNING, OF CROMWELL, CONNECTICUT.

IMPROVEMENT IN TEA AND COFFEE POTS.

Specification forming part of Letters Patent No. 35,457, dated June 3, 1862.

To all whom it may concerns

Be it known that I, Edward B. Manning, of Cromwell, Connecticut, have invented a new and useful Article of Manufacture of or Mode of Constructing Britannia Tea and Coffee Pots; and I do hereby declare that the following is a full, clear, and exact description thereof, and of its construction and mode or manner of operation, reference being had to the accompanying drawings, and to the letters of reference marked thereon, making a part of this specification.

Britannia metal, as is well known, is one of the cheapest and at the same time most beautiful materials for being formed into coffee and tea pots, as it can easily be given any shape and takes a high polish, but because of its liability to melt at a comparatively low temperature it is not well adapted to uses where brought in contact with highly-heated surfaces, as for drawing or boiling tea, &c. Block-tin and other metals more durable but less beautiful have therefore to a very considerable extent taken its place for such purposes.

My invention consists in constructing the lower body and bottom of Britannia tea and coffee pots of iron or a metal which will bear a very high degree of heat without injury, and in so uniting the two together that such vessel may have a flat bottom to rest directly upon the range, &c, and the two metals will not separate from each other or leak by any heat to which the vessel may be properly subjected.

Figure 1 is a perspective view of such a coffee-pot, the bottom, which is more heavily shaded, representing the iron or stronger metal. Fig. 2 is a detached view of the bottom part of firmer metal.

The upper part, A, is made of britannia, and may be formed in any shape desired. The lower part, B, is struck up, to correspond in shape with the upper part, out of iron or any metal which will bear a very high degree of heat without melting or being injured. Such part B is intended to be heavily tinned and polished, so as to be rendered as smooth and bright and elegant in appearance as the britannia itself, and thus the whole vessel harmonizes, as if made of the same metal. This lower part, B, is joined to the britannia part A at the line or joint a,which is some distance above the bottom, and far enough so that the heat of the range or stove upon which the vessel may be placed for drawwing or steeping tea, &c, will not loosen or make leaky the joint a.

In all the attempts that have heretofore been made to prevent Britannia coffee and teapots from being injuriously affected by the heat by combining some other metal with them such result has been sought to be obtained either by the use of feet or a ring or ledge placed under the vessel, or by making the bottom surface of copper, brass, or similar metal. In the former cases, when feet or a ring or ledge are used, the bottom of the coffee or tea pot is raised above the range or stove, and this interferes with the quick and proper action of steeping or boiling in such vessels. When the bottom surface of such articles have been made of firmer metal, the joints between the two different kinds of metal have been, in order to preserve the beauty and appearance of the pot, either directly on the edges of the bottom or just above it, so that the heated surface of the stove, &c, would act directly on such joint to unsolder it, or would be so near such joint as to produce the same effect, rendering the vessel leaky and useless. All such combinations have either raised the vessel from the heating-surface, thereby rendering the vessels less adapted, as every housekeeper knows, for the purposes for which intended, or the attached bottom has been extremely liable, if not certain, to become unsoldered and leaky whenever the pot was applied to its appropriate uses.

By my improved form and construction and of combining the firmer metal with the britannia the bottom of the vessel can be made and left flat, so as to come in close contact with the range, &c, thereby causing the operation of steeping, &c, to be quickest done, and in the preparation of tea and coffee the quickness with which the strength is drawn from the substance is very important and essential to the goodness of the decoction produced, and all danger or liability of the joint being loosened and the vessel rendered leaky is effectually prevented and obviated.

By heavily tinning the lower part of the vessel and polishing the same I can also produce a vessel of as neat and elegant appearance as if entirely made of britannia, but at the same time having all proper resistance to heat where such resistance is necessary.

Thus my invention or improvement does not consist in combining with or uniting to britannia a metal which will bear a greater degree of heat, but in so uniting the two metals by placing the joint or place of connection far enough from the bottom surface that such joints will not become leaky or destroyed by the heat, and securing a flat surface to rest on the heating-surface, and swaging the bottom part of the heavier metal into any artistic shape to correspond with the upper part of the vessel.

I do not claim the forming of pots and vessels of different kinds of metal, as this has been before done; but

What I claim as my invention, and desire to secure by Letters Patent, isó

An improvement in the construction of Britannia pots by making the lower body and bottom of such vessels of iron or a metal capable of bearing much greater heat than britannia, substantially as and for the purposes set forth.

E. B. Manning

Witnesses:

S. D. Law

Howard Bird

- Partnership: Robert Bowman and Joseph Henry Parsons, circa 1863-1870, in Meriden CT. As MANNING, BOWMAN & Co.

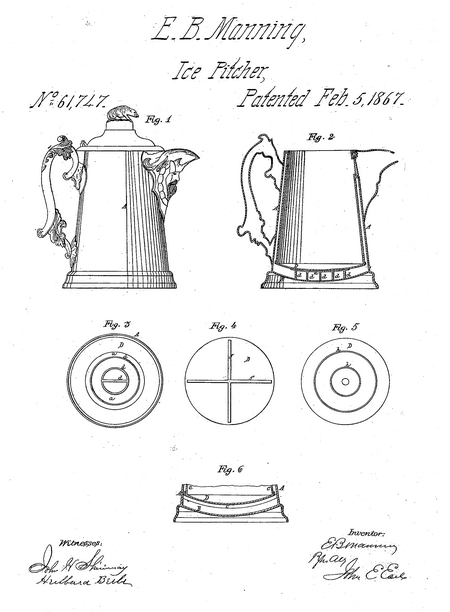

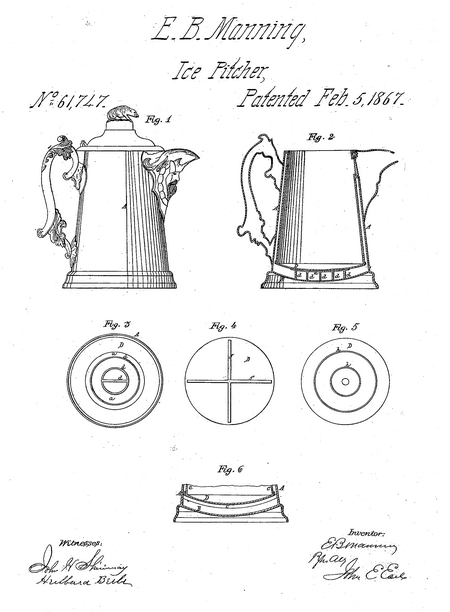

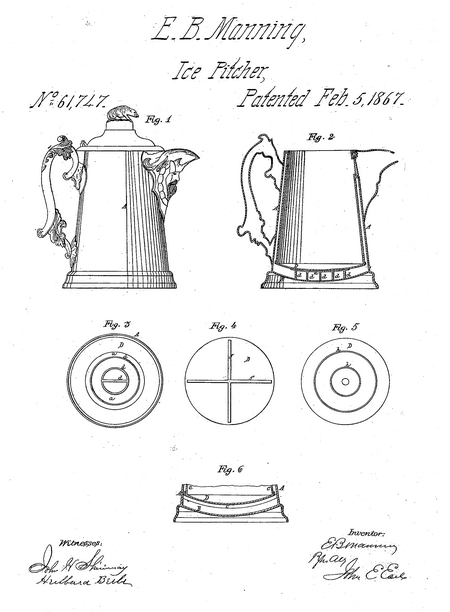

- He was issued patent number 61,747 on 5 Feb 1867

E. B. MANNING, OF MIDDLETOWN, CONNECTICUT.

Letters Patent No. 61,747, dated February 5, 1867. IMPROVEMENT IN ICE PITCHERS.

TO ALL WHOM IT MAY CONCERN:

Be it known that I, E. B. Manning, of Middletown, in the county of Middlesex, and State of Connecticut, have invented a new Improvement in Ice Pitchers; and I do hereby declare the following, when taken in connection with the accompanying drawings, and the letters of reference marked thereon, to be a full, clear, and exact description of the same, and which said drawings constitute part of this specification, and. represent, inó

Figure 1, a side view,

Figure 2, a vertical central section; and in,

Figures 3, 4, 5, and 6, different constructions of my improvement.

My invention relates to an improvement in the common ice pitchers, whereby the bottom is strengthened, tho object being to overcome an existing difficulty which arises from accidentally or carelessly dropping pieces of ice into the pitcher, which, striking the bottom, indent more or less, so that unless considerable care is exercised in placing ice in the pitcher, the bottom is soon injured to such an extent that repairs are necessary or the pitcher is useless; and to enable others to construct pitchers embodying my improvement, I will proceed to describe the same as illustrated in the accompanying drawings.

A is the outer case and B the bottom, to which it is attached; C, the inner case, and D the inner bottom attached thereto, all constructed so as to leave a space nearly or entirely around the inner case. This is the common construction, no other support being given to the bottom than the natural strength of the metal itself; therefore, when pieces of ice are dropped into the pitchers, unless great care is exercised, they strike heavily upon and indent the bottom D, which being frequently done, the bottom is soon pierced and the pitcher requires repairs, which are very inconvenient to make, if made at all. It may be proper to here remark, though it is well known, that the metal used in the manufacture of such pitchers is the common Britannia, -which is very soft and easily indented. This metal is used because it has no injurious effects upon the water, and does not rust. To overcome this difficulty, I place between the two bottoms D and B a hard metal plate, a, fitted to the under surface of the inner bottom D, (see fig. 2,) having formed thereon supports, d d, which rest upon, the bottom B. This is also seen in fig. 3, the supports d being flanges cast upon the plate a. The plate a fitting the under surface of the bottom D, prevents the indentation of the bottom D, as before described. This construction for supporting the bottom D I believe to be the most practical and cheapest; yet, if preferred, flanges, ff, more or less in number, as seen in fig. 4, may be soldered, brazed, or otherwise attached to or formed upon the bottom. D, the said flanges extending down and bearing upon the upper surface" of the bottom D; or circular flanges, h, may in like manner be fixed to or made a part of the bottom D, as seen in fig. 5, in like manner extending down to and resting upon the bottom B; or, as seen in fig. 6, bars, i, more or less in number, may be extended across beneath the bottom B and secured to the outer case A. This last is more expensive than the others, and has other serious objections, but is given in order to show that tho object of my invention may be accomplished in various ways.

Having thus fully described my invention, what I claim as now and useful, and desire to secure by Letters Patent, isó-

In combination with bottoms D and B, I claim the plate a, constructed and arranged so as to support the bottom D, substantially in the manner and for the purpose set forth.

E. B. MANNING

Witnesses:

James L. Hudson

T. H. Hall

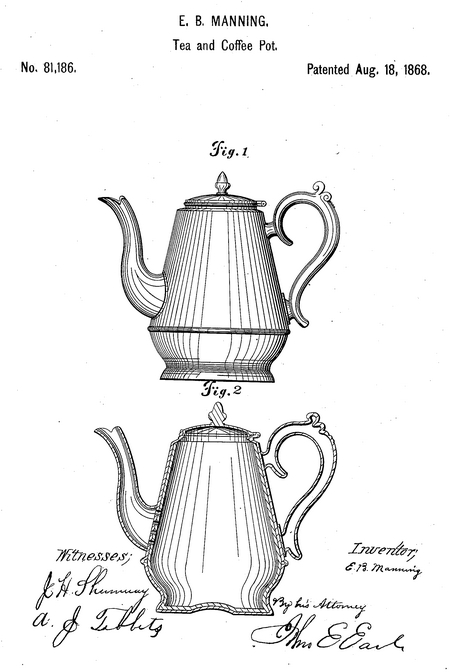

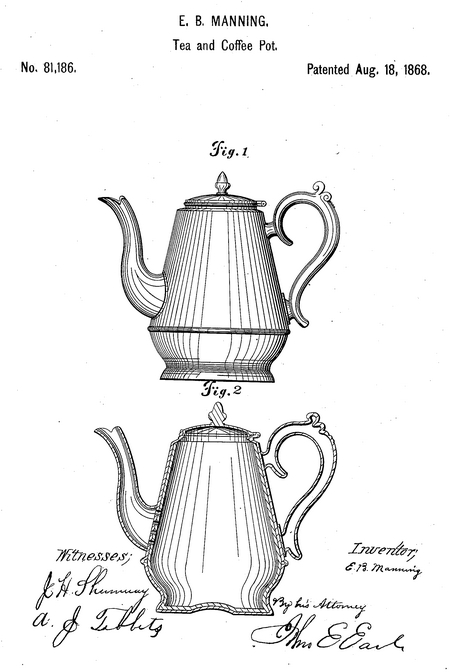

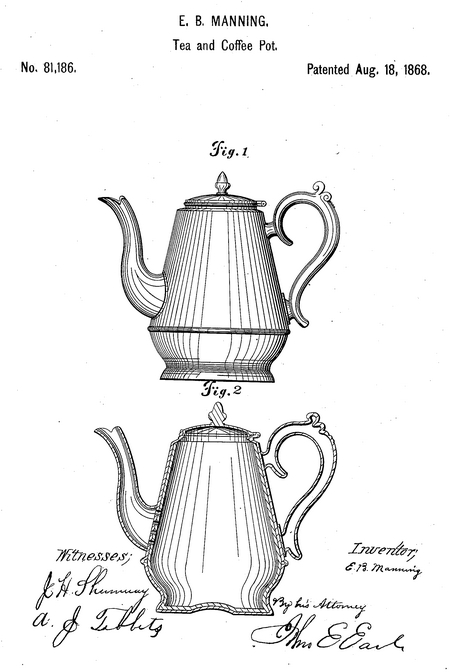

- He was issued patent number 81,186 on 18 Aug 1868

E. B. MANNING, OF MIDDLETOWN, CONNECTICUT.

Letters Patent No, 81,186, dated August 18, 1868. IMPROVEMENT IN TEA AND COFFEE-POTS.

TO ALL WHOM IT MAY CONCERN:

Be it known that I, E. B. Manning, of Middletown, in the county of Middlesex, and State of Connecticut, have invented a new Improvement in Tea and Coffee-Pots; and I do hereby declare the following, when taken in connection with the accompanying drawings, and the letters of reference marked thereon, to be a full, clear, and exact description of the same, and which said drawings constitute part of this specification, and represent, inó

Figure, 1 a side view, and in .

Figure 2 a vertical central section.

This invention relates to an improvement in the common Britannia or metal pots. It is a well-known and admitted fact that tea steeped in metal is more or less deleteriously affected by the metal, (so much so that a popular objection exists to metallic tea-drawers,) yet to earthen vessels for this purpose, the liability to breakage creates an objection. My invention, the object of which is to overcome these difficulties and combine in one the advantages of both, consists in a hard-metal body lined with porcelain or similar material hardened thereon, and after being so lined, the body is covered with a softer metal, as Britannia or tin.

To enable others to construct my improvement, I will proceed to describe the same as illustrated in the, accompanying drawings.

I construct a body of any desired form, according to the taste of the manufacturer or requirements of the trade, as denoted in solid black, fig. 2, then lino the body with the clay while in a plastic state, as denoted in red, fig. 2, and bake in the usual manner to harden the lining. Thus finished, I cover the outside of the iron body with a softer metal, as Britannia or tin, spinning the soft metal thereon so as to conform to.the iron body, as denoted in yellow, fig. 3; the spinning process giving all the security necessary for securing the outer coating of metal. I then perforate the outer metal body at the spout, to correspond to the perforations made in the iron and porcelain before the baking process, then attach the spout, handle, and cover in the usual manner, and I have produced a porcelain-lined tea-pot, which to all appearance is an ordinary Britannia or plated pot as the metal which forms the outer coating may be plated and burnished or finished in the usual manner.

For a tea-drawer, that is to say, a pot in which it is required to steep the tea, a soft-metal outside would be quite as liable to melt as an unlined pot; I therefore deem it advisable, in pots for this purpose, to make a hard-metal bottom and the lower portion of the body, as fully described in the patent granted to E. B. Manning, June 3, 1862, reissued, June 27, 1885, again reissued, September 26, 1865, for tea and coffee-pots.

Having thus fully described my invention, what I claim as new and useful, and desire to secure by Letters Patent, isó

A tea or coffee-pot constructed with a hard-metal or iron body, the inner side coated with porcelain or similar material, and the outer with soft metal after the lining has been baked, substantially in the manner herein set forth.

E. B. MANNING

Witnesses:

Joseph Gutman, Jr.

Edmund T. Davis

- He appeared on the census in 1870 in Middletown CT. Listed as a manufacturer of britannia wares.

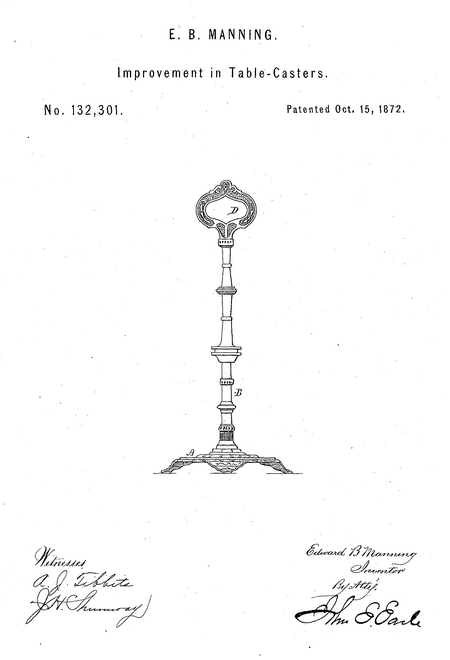

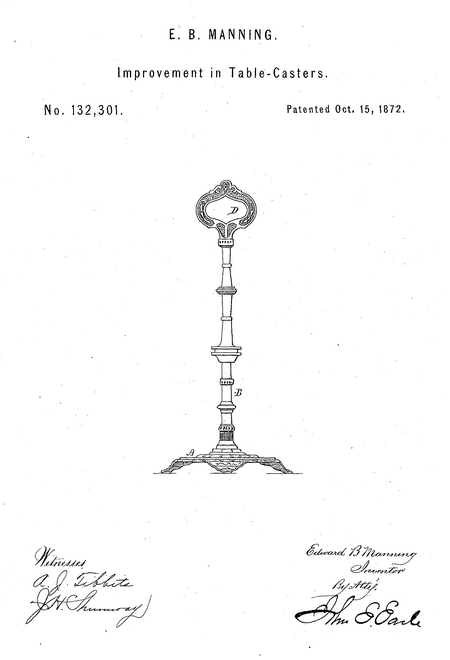

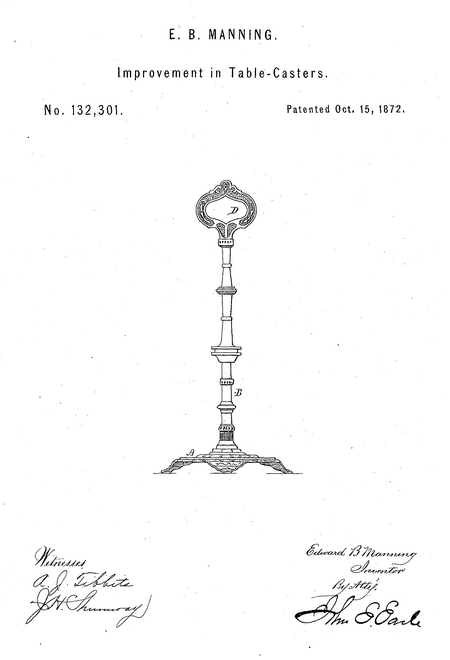

- He was issued patent number 132,301 on 15 Oct 1872

EDWARD B. MANNING, OF MIDDLETOWN, CONNECTICUT, ASSIGNOR TO MANNING, BOWMAN & CO., OF SAME PLACE.

IMPROVEMENT IN TABLE-CASTERS.

Specification forming part of Letters Patent No. 132,301, dated October 15, 1872.

To all whom it may concern:

Be it known that I, Edward B. Manning, of Middletown, in the county of Middlesex and State of Connecticut, have invented a new Improvement in Table-Casters; and I do hereby declare the following, when taken in connection with the accompanying drawing and the letters of reference marked thereon, to be a full, clear, and exact description of the same, and which said drawing constitutes part of this specification, and represents a side view of the base and handle.

This invention relates to an improvement in the construction of table-casters. As heretofore constructed the base of the caster has been made from white or other similar soft metal. This in use is easily bruised or bent; consequently, without extremely careful use, the base is soon marred or out of shape; and, further, that, as the bearing for the turn-table or center comes entirely upon this part of the caster, it quickly wears away, and the center is loose; and, further, the handle is easily bent, and no article of table use is so soon misshapen or disfigured as the caster. To overcome these difficulties is the object of this invention; and it consists in forming the base and center post from cast-iron plated with nickel.

A is the base cast in suitable molds from

iron, the center post B usually cast in the same piece. The ornamentation is cast in the surface and polished, and then plated with nickel. The base thus constructed cannot be bruised by use, and may be formed in delicate outlines, and with light feet upon which to rest, which, if formed from white metal, would render the article practically useless, so easily would it be bent out of shape. Formed from hard metal the turning of the center will not wear away but remain firm and strong. D is the handle, by preference formed in the same manner from cast-iron, thus giving to that part of the caster the same rigidity as that specified for the base. Another great advantage of this construction is that the base may be constructed at a very greatly-reduced cost, not only in material, but in the ornamentation.

I claim as my inventionó

As an article of manufacture, the base for a table-caster formed from cast-iron plated with nickel, and with or without the handle D, as specified.

E. B. MANNING

Witnesses:

Thomas H. Barowsky

James P. Walsh

- He appeared on the census in 1880 in New Haven CT. Listed as a silverplater.

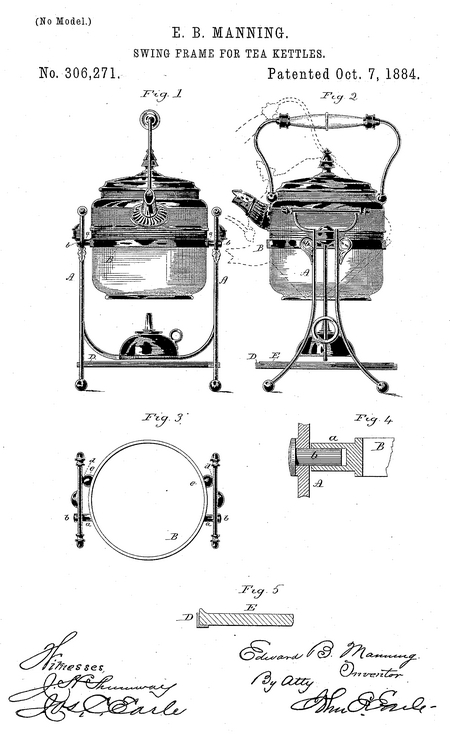

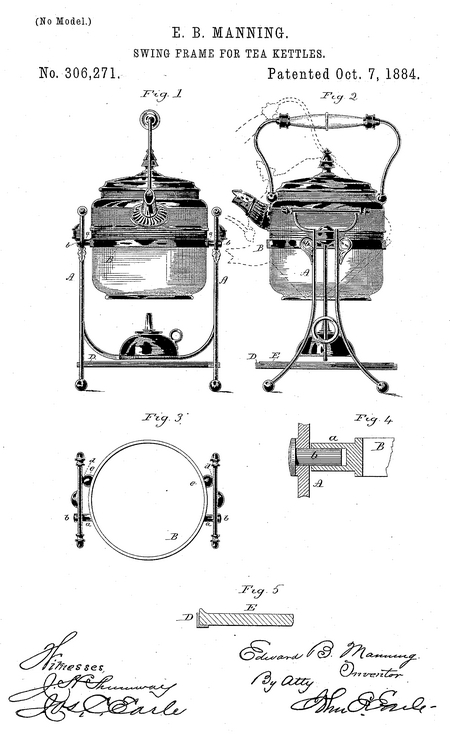

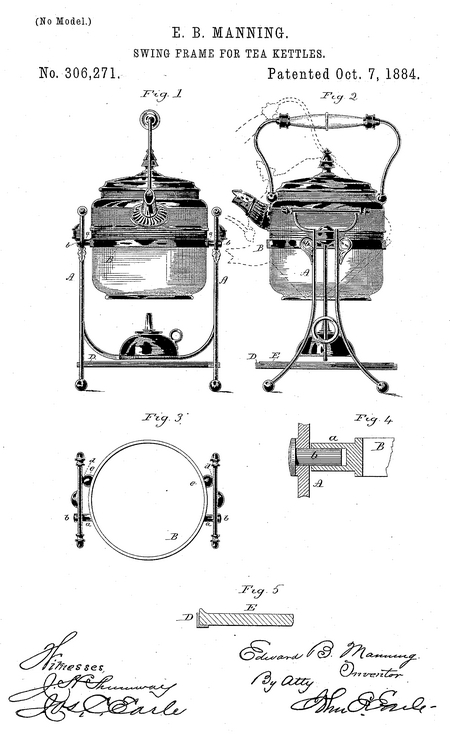

- He was issued patent number 306,271 on 7 Oct 1884

EDWARD B. MANNING, OF MERIDEN, CONNECTICUT.

SWING-FRAME FOR TEA-KETTLES.

SPECIFICATION forming part of Letters Patent No. 306,271, dated October 7, 1884.

To all whom it may concern:

Be it known that I, Edward B. Manning, of Meriden, in the county of New Haven and State of Connecticut, have invented a new Improvement in Swing-Frames for Tea-Kettles; and I do hereby declare the following-, when taken in connection with accompanying drawings and the letters of reference marked thereon, to be a full, clear, and exact description of the same, and which said drawings constitute part of this specification, and represent, inó

Figure 1, a front view; Fig. 2, a side view: Fig. 3, a top or plan view, the kettle removed; Fig. 4, a section through the trunnion; Fig. 5, a section through the plate below the lamp.

This invention relates to an improvement in that class of kettles which are designed for table service for hot water, tea, &c, and which are hung in a frame so that the kettle will stand over a lamp, and so that the kettle may be tilted without detaching it from the frame. In the more general, construction of this class of kettles and frames a trunnion is applied to the kettle at opposite sides, to rest in a corresponding seat in the frame. The attachment of such a trunnion to earthen kettles or pots is a difficult thing to do, and when attached either to earthen or metal pots is in the way when the pot is in use upon the frame, and anything but an ornament to the pot or kettle. Again, no kettle.is adapted to the frame unless it be provided with such trunnions; hence if the kettle be broken the whole article is useless.

The object of my invention is, principally, to construct a frame in which the tilting trunnions are not necessarily applied directly to the kettle; and it consists in a frame having a ring hung upon trunnions, the said ring in diameter corresponding to the kettle or pot to be placed thereon, and so that the kettle may be set within the ring and be supported thereby on the trunnions between the ring and frame, as more fully hereinafter described.

A A represent the two uprights of the frame, which may be of any desirable configuration or design. Between the uprights the ring B is arranged. This ring B is made from metal, and at opposite points forward of the central line a trunnion, a, is applied. This trunnion takes a bearing in the frame, preferably as seen in Fig. 4. The trunnion is made tubular, and a pivot, b introduced through the frame into the trunnion. In rear of the central line, on one or both sides, a lug, d, is formed on the ring, to strike corresponding' stops, e, on the frame. The trunnions or pivots being forward of the central diametrical line, thegreater portion of the weight of the ring is in rear of the pivots; 'hence by its own gravity the ring will rest upon the stops e in its horizontal plane. The kettle is set into the ring, as shown, its diameter corresponding to the diameter of the kettle, so as to support the kettle when in its proper position, and in that condition the kettle may be tilted, as indicated in broken lines, Fig. 2. The kettle may be of any material or construction, it only being necessary that it shall be of such a size as to take a bearing within the ring. The trunnions being a permanent or fixed arrangement, there is no difficulty in introducing the kettle to the frame, for the ring itself forms a guide for so doing, and thereby avoids frequent accidents, which occur from misplacing the kettle where the trunnions are a fixed part of the kettle.

In this class of kettles the heating device is a lamp, C, seated in the frame below the kettle. The lamp is necessarily small, and is usually lighted upon the table. Under the most careful usage the lamp is liable to overflow, carrying the flame upon the table-cloth beneath. To avoid this difficulty, as well as to make the frame more highly ornamental, I attach to the frame below the lamp a metal ring, D. The inside of this ring is constructed, as shown, to receive a pottery tile or plate, E, the edge of the plate raised so as to form a recessed top. Any overflow from the lamp or drip from the kettle will be caught upon this plate, and the cloth thereby protected. This plate, in addition to its utility, makes a highly ornamental feature in the frame.

I am aware that a swinging support has been arranged upon trunnions in a frame to receive and hold a kettle so as to be tilted; but these have been of a pendulum-like characteróthat is, the trunnions above the bearing point or rest for the kettle, and in substantially a vertical plane; but I am not aware that a frame has been provided with a ring having trunnions in the horizontal plane of the ring, and forward of the vortical central plane of thering, with stops in rear of the trunnions, and whereby the ring turns upon its pivots, instead of the pendulum-like spring of the previous construction.

I claimó

1. The herein-described improvement in swing-frames for tea-kettles, consisting in the ring B, provided with trunnions forward of its vertical central line, and in the horizontal plane of the ring, seated in corresponding bearings in the frame, and provided with stops in rear of said trunnions, said ring being adapted to receive and support the kettle, and permit the kettle to be tilted, substantially as described.

2. In a swing-frame for tea-kettles, the flanged ring D, arranged below the kettle-support, combined with the plate E, recessed upon its upper surface, and arranged within said ring D, substantially as described.

Edward B. Manning

Witnesses:

A. L. Stetson

A. F. Hall

|