Albert C. Sweetland

- Born: Abt 1830, Attleboro MA

General notes:

Jeweler

Events in his life were:

- He appeared on the census in 1855 in Attleboro MA. Listed as a machinist.

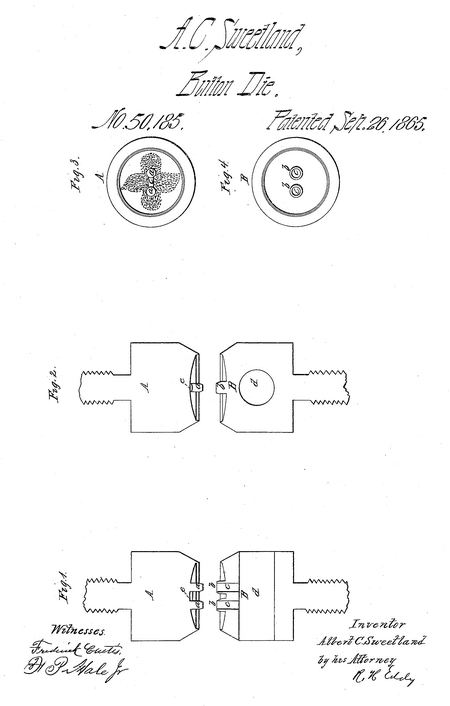

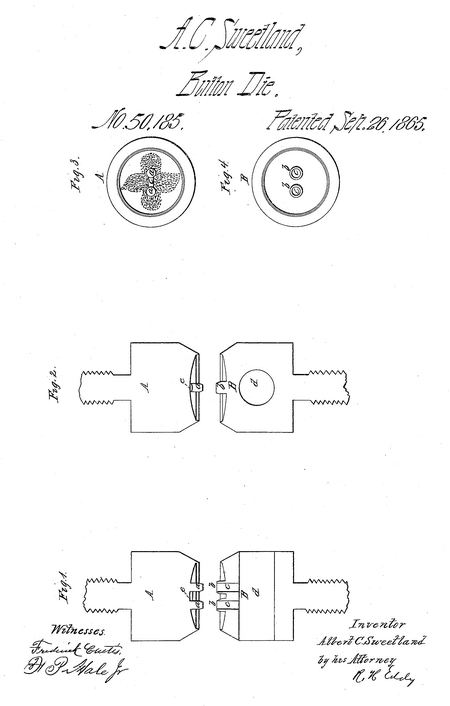

- He was issued patent number 50,185 on 26 Sep 1865

ALBERT C. SWEETLAND, OF NORTH ATTLEBOROUGH, MASSACHUSETTS

DIE FOR MAKING BUTTONS

Specification forming part of Letters Patent No. 50,185, dated September 26, 1865.

To all whom it may concern:

Be it known that I, Albert C. Sweetland, of North Attleborongh, in the county of Bristol and State of Massachusetts, have invented a new and useful improvement in molds or dies for making buttons from, glass or other material capable of being shaped thereby; and I do hereby declare the same to be fully described in the following specification and represented in the accompanying drawings, of which—

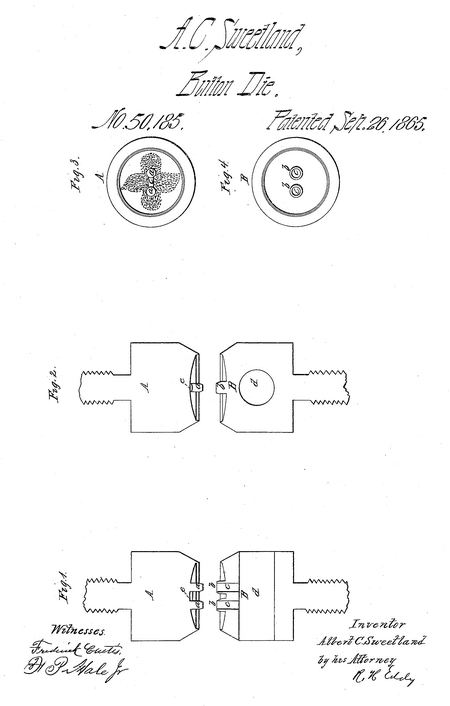

Figures 1 and 2 are vertical sections of a pair of button-dies provided with my invention. Figs. 3 and 4 are separate views of such dies.

Instead of making the dies with the ordinary simple punches only for forming the eye-holes in the button, I combine with such punches and such dies tubular counter-punches, whereby the eye-holes are formed without burrs and are properly countersunk.

In the drawings, A and B are the upper and lower dies of a pair of button-forming dies, a a being the eye-hole punches projecting from the base of the upper die, and b b being the counter-punches extending from the face of the lower die. The punches b b are tapering externally, and each is provided with a passage, v, for reception of the fellow punch a, and also for discharge of the material separated from the mass by the punch a, such material being caused to drop into a cross-passage, d, made through the body of the die. There projects also from the face of the upper die and between the two punches a a thereof, and so as to extend from one to the other of them, a groove-former, e, shaped as shown in the drawings, its purpose being to form in the button a groove extending from one eye to the other and for the reception of the thread used in fastening the button to an article, the groove being for the protection of the thread.

By means of the main and tubular counter-punches combined with the button-dies, eyeholes formed in a button by such dies will not only be countersunk, but be made without any burrs or ragged edges calculated to cut or wear the fastening-thread when the button is fixed to a garment.

In using the dies, the glass, while in a semi-molten or soft state, is to be placed between and be compressed by them. On being removed from the dies the mass of glass will be in the form of a button.

I claim—

I. The combination of a counter-punch, b, and the discharging-passage c thereof with the dies A B and each of the main punches a thereof, the whole being arranged substantially as and to operate as specified.

2. The combination and arrangement of the groove-former e with the upper of the two dies A B and their punches a a, the whole being as explained.

Albert C. Sweetland

Witnesses:

Henry Reis

W. C. Draper

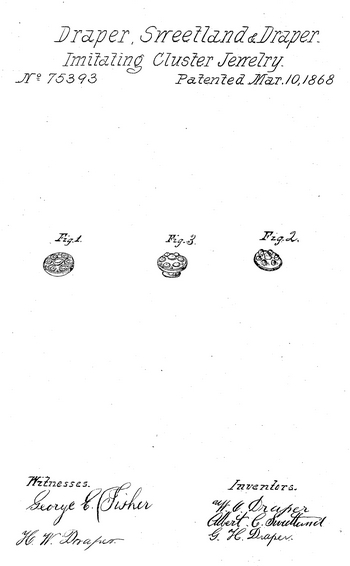

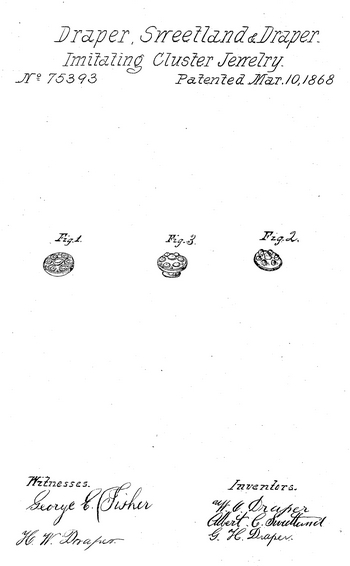

- Patent: 75,393, on 10 Mar 1868. WILLIAM O. DRAPER, ALBERT O. SWEETLAND, AND GEORGE H. DRAPER, OF NORTH ATTLEBORO, MASSACHUSETTS.

Letters Patent No. 75,393, dated March 10, 1868.

MODE OF IMITATING CLUSTER-JEWELRY.

To All Whom It May Concern:

Be it known that we, WILLIAM O. DRAPER, ALBERT C. SWEETLAND, and GEORGE H. DRAPER, all of North Attleboro, in the county of Bristol, and State of Massachusetts, have invented a new and useful Improvement in the Method of Making Imitation Cluster-Jewelry; and we do hereby declare that the following specification, taken in connection with the drawings making a part of the same, is a full, clear, and exact description thereof.

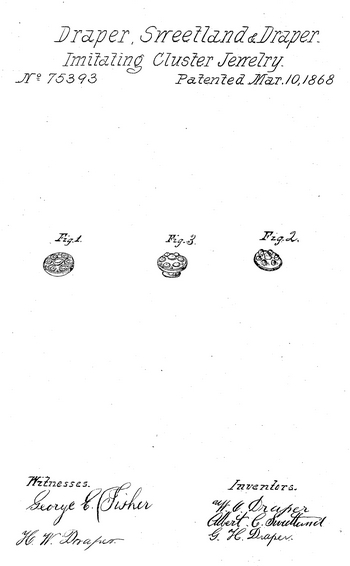

Figure 1 represents a perforated plate, which, when combined with the stone, will form the apparent setting.

Figure 2 represents the form in which the colored glass imitating the stones is prepared.

Figure 3 exhibits a specimen of the finished article.

Heretofore "cluster-work," or that style of jewelry which, in the form of breast-pins, buttons, ear-rings, &c., consists of an aggregation of small stones arranged in a cluster, has, in the case of imitation jewelry, as in that which is genuine, been made by mounting each stone, or its glass imitation, in an appropriate plate, furnished with as many settings as there are stones, each stone being held in the grasp of its appropriate setting by the friction, of the edge of the latter against the surface of the stone.

In the manufacture of genuine work this method is the only one practicable, on account of the small size and high value of the jewels employed. In imitation-work, where colored glass, in place of precious stones, is employed, the method of constructing which is the subject of the patent can be employed, and the object of which is to produce an article which shall have at least the merit of excelling the ornament which it counterfeits in point of durability and strength.

Instead of making use of separate "stones," as the colored glass used for the purpose is called, we employ a glass disk of any desired hue, the top surface of which is furnished with bosses of the same material, arranged of any size and according to any pattern suitable for the intended article. A specimen of this bossed plate is shown at fig. 2, and the same, and others of any pattern, can be readily moulded by glass-workers. In place of the setting heretofore used, we employ a perforated cap, fig. 1, which may be of very thin sheet metal. It should have its edge turned over to form a rim, so as to admit of its being burnished against the edge of the glass plate, or to be soldered to the back-plate if a back-plate of metal is used. The perforations in the plate should correspond in form with the base outline of the bosses, and should be arranged in the same pattern. This perforated plate can readily be made by means of dies and formers of proper shape operated in a jeweller's press, as is well understood.

The article is completed by placing the plate over the glass disk, fig. 2, so that the bosses upon the latter will protrude through the perforations, and by burnishing the wire against the edge, or soldering it to the back plate, as before stated. The attachments necessary to make the article into a button, breast-pin, or other, article, can now be added, as in other cases.

Not only, by the method of making the article described, is it impossible for any one of the stones forming the cluster to become detached, but the cost of making it is very much less than the cost of making the same article in the old way.

What we claim as our invention, and desire to secure by Letters Patent, is—

The method of constructing cluster-work jewelry, substantially as herein described.

W. O. Draper

Albert O. Sweetland

G. H. Draper

Witnesses:

George E. Fisher

H. W. Draper

- He appeared on the census in 1865 in Attleboro MA. Listed as a jeweler.

- He appeared on the census in 1870 in Attleboro MA. Listed as a manufacturing jeweler.

|