Charles Smith Capron

- Born: 28 Dec 1814, Providence RI

- Marriage (1): Susan Palmer

- Died: 28 Dec 1898, Providence RI

General notes:

Jeweler

Events in his life were:

- Patent: 24,432, on 14 Jun 1859. JOHN S. PALMER

, OF PROVIDENCE, RHODE ISLAND, ASSIGNOR TO HIMSELF AND CHAS S. CAPRON OF SAME PLACE

ROLLING METAL FOR JEWELRY.

Specification of Letters Patent No. 24,432, dated June 14, 1859.

To all whom it may concern:

Be it known that I, JOHN S. PALMER, of Providence, in the county of Providence and State of Rhode Island, have invented a new and useful Method of Roiling Out Jewelry; and I do hereby declare that the following is a full, clear, and exact description of the same, reference being had to the accompanying drawings, forming part of this specification, in which—

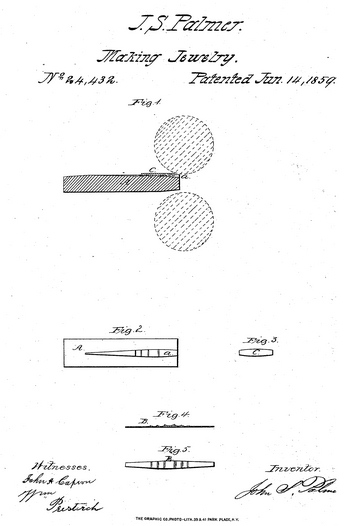

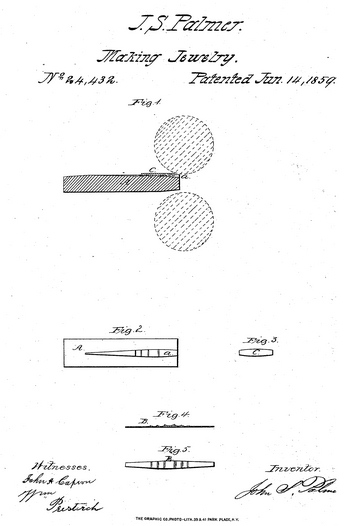

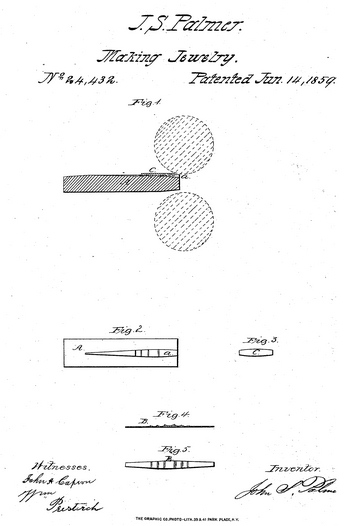

Figure 1 represents a longitudinal central section of the die which I use in rolling out articles of jewelry. Fig. 2 is a plan or top view of ditto. Fig. 3 is a plan of the stock from which a certain article of jewelry is to be manufactured. Fig. 4 is a longitudinal vertical section of the article after having been rolled out and Fig. 5 is a plan or top view of ditto.

Similar letters of reference in the several views indicate corresponding parts of my invention.

In rolling out articles of jewelry or in fact any other article the usual method is to pass the stock through between pressing rollers, or to place the stock on a die and pass pressing rollers over it, commencing at one end of the stock and rolling through to the other end or as far as the nature of the work requires. By doing this the stock is stretched from one end toward the other, and when it becomes necessary to raise certain portions of the work, such as the scale of a finger ring, the rolling in this manner was found to be insufficient, as by a continuous rolling from end to end the stock is carried forward and there is not sufficient remaining to fill the end of the scale. In order to produce such articles as the scale of a finger ring for instance, it has been necessary, to attach to the original plate an additional thickness of metal by soldering or by some other means, causing much more labor than would be required if the whole could be made out of one piece.

To accomplish this, namely to produce articles of unequal thickness and with the thickest part in the center by rolling, is the object of my invention, which consists, in arranging a tapering die with a suitable groove, in such a manner, that when the stock is placed on the same and it together with the die is passed through between a pair of pressing rollers, these rollers take first on the middle of the stock, whereby the same is pressed down into the deepest part, in the middle of the groove and it is drawn out toward one end and formed as directed by the groove, and by turning it the other end is rolled out in the same manner, so that I am enabled to raise the scale of a finger ring or any other similar article with perfectly sharp corners and of any depth. To enable those skilled in the art to fully understand, use, and construct my invention, I will proceed to describe it. A is a die made of steel and sufficiently thick to resist a very strong pressure. The upper face of this die is provided with a groove a the bottom of which is shaped according to the article of jewelry to be rolled by it. The groove represented in the die A in Figs. 1 and 2 is made for a ring, and it is intended to roll out a plate B as represented in Figs. 4 and 5. By referring to Fig. 4 it will be seen that the plate has its thickest part in the middle, from whence it is gradually thinning down toward both ends and several moldings on each side are intended to give to the ring a more ornamental appearance. The bottom of the groove a shows the same moldings reversed, those parts which are to be the highest on the plate B, being the lowest in the groove as will be easily understood from Fig. 1, and as the plate B becomes gradually thinner and narrower toward both ends, so the inner end of the groove a has to be made running out gradually to the surface of the die as represented in Fig. 1 and becomes narrower from the middle toward its end as clearly represented in Fig. 2. The front end of the die A is chamfered off at its under side and the groove a is made deep enough so that the pressing-rollers don't begin to act on the stock C, which is placed on the die as represented in Fig. 1 in red lines, before the die has passed far enough between the same so as to form the middle part of the plate B first. The stock is of uniform thickness throughout and thick enough to form the thickest part of the article to be rolled, and it is of such a shape that it just fits into the widest part of the groove a.

The operation is as follows: The stock is placed on the die as represented in Fig. 1 and the die is passed through between the pressing rollers, and the stock is not taken any thicker, than necessary to fill up the deepest part of the groove a, and as the die is so shaped, that the pressing rollers take first right above the deepest part of the groove a, the stick is pressed down into this part and its end is gradually thinned out toward the end of the groove, following the latter, and filling up all the inequalities on its ground. The stock is now taken out and its other end, which preserved its original thickness during the first part of the operation is placed on the die and passed through between the pressing rollers and it is drawn out in the same manner, following the groove a from the middle or deepest part of the same to its end. It is obvious that, with a die of uniform thickness from end to end, this object cannot be obtained, without the use of a male and female die or some part to take the place of the male die, whereas by making the die tapering on its front end I am enabled to raise the scale for a finger ring or other parts of similar articles with perfectly sharp corners and of any depth, nothing else being required but a female die and a pair of smooth pressing rollers.

Having thus fully described my invention what I claim as new and desire to secure by Letters Patent, is,

The employment of a tapering die A, in combination with the pressing rollers, substantially as and for the purpose specified.

John S. Palmer

Witnesses:

John A. Capron

Wm. Prestwick

- He appeared on the census in 1860 in Providence RI. Listed as a manufacturing jeweler.

- He appeared on the census in 1880 in New York City NY. Listed as a jeweler.

Charles married Susan Palmer, daughter of Gideon Palmer and Elizabeth Simmons. (Susan Palmer was born on 4 Mar 1818 in Providence RI and died on 19 Apr 1882 in Providence RI.)

|